Page 3

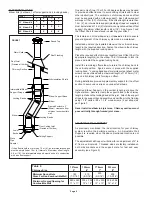

The chimney should be located within the building so as to avoid

cutting or altering load bearing members such as joists, rafters,

studs, etc. If you require to cut or alter an existing load bearing

member, special reframing methods are required which often

include doubling of adjacent members. If such a case arises, contact

your local Building Code Official regarding local regulations and

proper installation methods.

Model UT chimney requires 2” (50mm) clearance to

combustible material or as established by support

assembly.

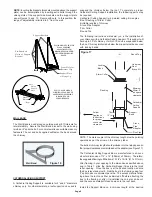

Attach flue pipe parts securely to each other, and to the appliance

using three sheet metal screws per joint.

•

Be sure that ladders are in good condition and always

rest on a level firm surface.

•

Be very careful around electrical wiring and be sure it is

secured at least 2 inches away from any part of the chimney. If

wiring must be relocated, hire a professional electrician.

Do not place any type of insulating materials or run any

electrical wiring within the required clearance air

space surrounding the chimney.

FUELS & APPLIANCES:

Model UT chimney has been designed for connection to liquid

fuel or gas fired residential type appliances and building heating

appliances, in which normally producing flue gases of 540° C

(1000° F) or less. Model UT may also be installed with specific

factory built fireplaces where specified in the manufacturers

installation instructions and identified on the fireplace rating label.

Model UT chimney is listed for use with Selkirk fireplace models.

Before commencing the installation ensure that you obtain any

necessary building permits, and that your installation will conform

with all federal and municipal building codes requirements

affecting the fuel-burning appliance and its chimney. This

chimney is intended for use in accordance with:

- National and Provincial Building Code of Canada,

- CAN/CSA B-149.1-00 Installation Code for Gas Equipment,

- CAN/CSA B-139.00 Installation Code for Oil Burning Equipment;

- Appliance and venting manufacturers’s Installation Instructions.

TOOLS:

Your UT chimney system is designed for installation using

standard building materials and procedures. The following tools/

equipment may be required as well as some others depending

on the location and structure in which the chimney is to be

installed:

Sections of the UT chimney which pass through accessible areas

of the building such as closets, storage areas, occupied spaces

or anyplace where the surface of the chimney could be contacted

by persons or combustible materials must be enclosed in a

chase to avoid personal contact and damage to the chimney.

Enclosures may be fabricated using standard building materials

such as 2” x 4” wood framing with gypsum drywall or plywood

walls and must have a fire rating equal to or greater than the

floors or ceilings through which the chimney passes.

-Safety gloves

-Safety goggles

-Hammer and nails

-Tin snips

-Tape measure

-Scewdrivers and pliers

-Plumb line and level

-Square

-Keyhole say or power jig saw

-Caulking gun and caulking

•

Be sure that electrically powered tools are properly

grounded.

If you are knowledgeable in carpentry and mechanically inclined,

you can take on the task of installing your new venting system. It

is important that all pertaining installation instructions and local

codes are followed carefully. If you have any doubt concerning

your ability or knowledge of the appliance being connected to

your chimney system, arrange for a professional installation.

Certified technicians having installed systems many times

before have the knowledge and experience to perform your

installation in a professional and timely manner.

YOUR CHIMNEY HAS BEEN TESTED, AND LISTED

USING ALL OF THE SUPPORTS, SHIELDS, ETC.,

DESCRIBED HEREIN. DELETION OR MODIFICATION

OR ANY OF THE REQUIRED PARTS OR MATERIALS

MAY SERIOUSLY IMPAIR THE SAFETY OF YOUR

INSTALLATION, AND VOID THE CERTIFICATION AND

OR WARRANTY OF THIS CHIMNEY

WEAR SAFETY GLOVES WHEN HANDLING

SHEET METAL PARTS WITH SHARP EDGES

MAINTAIN A 2” (50MM) MINIMUM AIR SPACE CLEARANCE

BETWEEN THE INSULATED CHIMNEY SECTIONS AND

COMBUSTIBLE MATERIALS

The chimney pipe and fittings must be assembled with locking

bands or stainless sheet metal screws, maximum length of 1/2”

(12.70mm) on all interior joints. Locking bands must be used

on all exterior joints.

Support all offsets with an offset support and adequate strapping.

RULES FOR SAFETY DURING INSTALLATION:

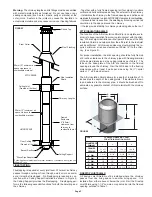

CHIMNEY SIZING:

The correct chimney size is essential to the efficient operation of

the chimney and the appliance which it serves. Consult the

appliance manufacturer’s installation instructions or your dealer

for proper chimney diameter size. Plan the installation of your

appliance and chimney in such a way that both your chimney

and flue pipe runs are as short and straight as possible. By

having too long and/or multiple bend installations you can reduce

system draft which can affect the operation, and/or performance

of your appliance and/or chimney system.

NOTE:

The ideal location for your chimney system is within the

building envelope. In cold climates, the use of external chimneys

may result in operational problems such as poor draft, excessive

condensation of combustion products and rapid accumulation

of creosote. Under these circumstances, the installation of the

chimney within the building is strongly recommended.

If the chimney must be installed on an exterior wall it is recom-

mended that the chimney be enclosed below the roof line to

protect the chimney from cold outdoor temperatures, this may

help reduce condensation, creosote formation and enhance draft.

Provide an access door by the Tee Cap for chimney inspection

and cleaning. The exterior enclosures may be insulated, main-

taining the required minimum air space clearance of 2” (50mm)

to any part of the chimney. Consult local building codes for cold

climate applications.

GENERAL INSTALLATION RULES: