Page 4

2"

(50mm)

Min

2"

(50mm)

Min

2" (50mm)

Min

2"

(50mm)

Min

1-1/2”

4-1/8”

3”

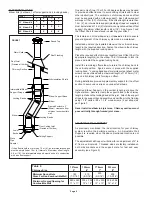

INSTALLATION PROCEDURES:

CEILING SUPPORT

To complete a proper Ceiling Support installation, the following

parts may be required.

- Ceiling Support: For joist supported chimney system.

- Attic Insulation Shield: Where a chimney enters an open attic

space.

- Firestop Joist Shield: Installed where the chimney passes from

one living space to another living space or as specified in the

listed factory-built fireplace installation instructions.

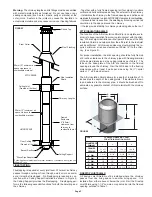

Authority require that the chimney extend not less than 3ft (900

mm ) above the highest point where it passes through the roof of

a building and not less than 2ft (600 mm) higher than any portion

of a building within 10ft (3m) horizontally. See Figure 1 and Chart

2 in the back of these instructions.

FRAMING DETAILS:

Plan your installation carefully. If possible, position the appliance

so that the flue outlet is centered between joists, rafters or studs.

Drop a plumb line to the center of the flue outlet and mark this

center point on the ceiling. Lay out and frame all openings

ensuring the specified 2” clearance to combustibles is main-

tained. All openings should be square, plumb and in perfect

alignment with each other (see Figure 2). For angled roofs, en-

sure that the framing dimensions are measured on the horizon-

tal plane (see Figure 3).

FRAMING DIMENSIONS FOR MODEL UT

TO MAINTAIN 2 INCH AIR SPACE CLEARANCE

MODEL UT

Chimney Inside

Diameter:

All other framing*

Ceiling Support*

*All framing dimensions may be up to 1/2” more, but not less than the above values.

Table 1

The following instructions will assist you in the installation of your

chimney with a Ceiling Support. This support will hold up to 15.25m

(50’) of chimney sections, all of which must be installed above the

support.

1. Frame a level square opening (all four sides). Inside dimen-

sions should conform to Table 1.

2. With the Lower Bucket removed, place the upper bucket

assembly into the framed opening from below.

3. Ensure that the support plate is level and flush and drive one nail,

1-1/2” common or spiral, part way into each of the four (4) nailing

areas of the support. You may substitute nails with #8 x 1-1/2” wood

screws.

4. Finish nailing through all prepunched holes (12 nails total) and

fasten the finishing (support) plate to the ceiling (see Figure 4).

5. Replace the Bucket Section from above. Connect the proper

sized Stove Pipe Adapter to the first chimney length. Lower this

chimney section down into the bucket section, with the male end

pointing upwards as indicated by the arrow on the chimney label.

6. Additional chimney lengths above the support are simply

stacked on, twist locked with a 1/8 clockwise turn and secured

with a locking band at each chimney joint. A locking band is

supplied with every chimney length and must be used on all

chimney joints, interior or exterior. Stainless steel sheet metal

screws (maximum length of 12.70mm (1/2”) may be substituted

on interior joints.

7. Finish the chimney to its required height.

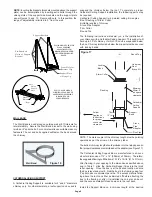

8. If an offset is installed in the system, an Offset Support must be

installed as shown in Figure 7.

9. If the chimney extends 5 feet (1.5 m ) or more above the roof,

additional lateral support is required, such as the Universal Roof

Brace Kit.

3 ft.

(900mm)

min.

2 ft.

(600mm)

10 ft.

(3m)

2ft.

(600mm)

3 ft. (900mm)

min.

FIGURE 1

- Roof Flashing: Required when the chimney penetrates a roof.

- 15° , 30° or 45° Elbow Kits (2 per box with locking bands and

elbow support).

- Suitable lengths of chimney: Available in 6”, 12”, 18”, 24” and

36” lengths. A 48” length is available in 6” and 8” only.

- Round Top

- Stove Pipe Adapter

Chimney Length

Lower Bucket

Upper Bucket

The Ceiling Support is intended for installation below a finished

or unfinished ceiling.

Figure 4

Cathedral Support

Support Plate

Stove Pipe Adapter

Figure 3

Typical Roof Joist

Framing

Figure 2

Typical Joist Framing

5” 6” 7” 8”

10 1/4”

12 1/4”

11”

11 1/4”

N/A

13”

12 1/4”

N/A

14”

10 1/4”

12 1/4”

12”