Page 8

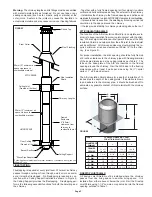

Insulated Wall Thimble

Telescoping adjustment

from 6” to 11”

Insulation

Blanket

Interior Inner

Half of

Insulated Wall

Thimble

Exterior Outer

Half of

Insulated Wall

Thimble

Figure 11

Insulated Wall

Thimble

Combustible Inside Wall

76mm (3”) min.

660mm (26”) max.

Insulated Chimney

Length

Min. Clearance to

Combustibles (50mm)

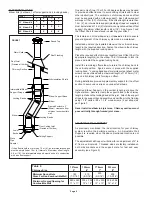

Fig. 13 - Wall Support

Installation

Lag Screws Into

Structure

Bracket

Support Plate

Wall Support Kit

Locking Band

Insulated Tee

Full Enclosure

Recommended.

Both Indoors

and Outdoors

Use Locking

Bands on All

Joints

Wall Band Every

8 Feet

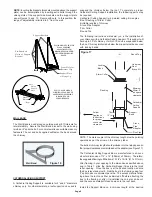

9. Place the insulated Tee on the support plate ensuring that the

male coupler of the Tee is facing up and the flange on the top of

the plate slides into the female coupler. Insert and secure the Tee

Cap with the attached retainer clips (see Figure 12). In earthquake

zones, secure the Tee to the flange on the support plate by

installing 2 stainless steel sheet metal screws as per figure 12.

10. For extension of the Tee, slide an appropriate insulated

Chimney Length through the Wall Thimble and attach it to the

horizontal branch of the Insulated Tee with the supplied locking

band. Make sure the nut and bolt are facing down to prevent any

water from collecting in the locking band. The insulated length

must protrude at least 76mm (3”) through the wall into the room

as per Figure 13.

Stud and Nut

located to front

of Support

Bracket

Support

Brackets

Threaded Stud

and Nut

located at

rear of

Support

Plate

Pre-

Punched

Holes of

Support

Bracket

Flange Up

Holes for Retainer Clips

FIG. 10 - FRONT VIEW OF WALL SUPPORT ASSEMBLY

Support

Plate

6. Ensure that the Wall Support is level, and secure to the wall

through the pre-punched holes located on the sides of each of

the wall support brackets using (8) #14 x 1-1/2” hex head lag

screws or #10 x 1-1/2” wood screws. You can drill 5/32” pilot

holes for the lag screws.

7. Once in its final position and all clearances have been met,

tighten each of the nuts on the threaded studs.

8. Attach the two (2) retainer clips to the bottom of the support

plate and fasten with the supplied nuts and bolts using the two

(2) holes on top of the support plate (see Figures 10 & 12).

FIG. 12 - SECURING OF TEE CAP

Support

Plate

Retainer

Clip

Tee Cap

Earthquake zones

secure Tee to the

Support Plate

with stainless

steel screws

Insulated Tee

WARNING: Tee Cap and Retainers must be installed.

Failure to install retaining clips could cause fire,

injury or death.

Wing Nut

11. Use a non-hardening high-temperature sealant (500

o

F) to

seal around the horizontal length where it enters the wall thimble

or the concrete wall.

12. Chimney lengths above the Insulated Tee are simply stacked

on and locked with a 1/8 clockwise turn. Locking bands must be

used on all joints.

13. For lateral stability of the chimney above the support, a Wall

Band must be used every 8 feet, and at least one Wall Band

must be installed. Interior chimneys must use the Firestop Joist

Shield (JS) in place of Wall Bands if extending through floor /

ceiling penetrations.