CLEARING A PAPER JAM

Should a jam occur, the machine will turn itself off. Ensure that all personnel

are clear of both the input conveyor and the cutter head.

Momentarily depress the yellow Reverse pushbutton. This will cause both

the conveyor and the cutters to run backwards for as long as the Reverse

pushbutton remains depressed.

Release the Reverse pushbutton. The machine will come to a stop. After the

machine has completely stopped, remove some of the offending material.

Re-start machine in the forward direction to resume operation.

NOTE:

This machine has been engineered to allow paper to be fed with paper clips,

staples, fasteners, credit cards, aluminum offset plates, and similar materials

without harm to the machine.

SHUT-DOWN PROCEDURE

Allow input conveyor and output chute (or optional output conveyor) to clear

all material before shut down.

Depress red Stop pushbutton. Remove power cable from receptacle.

Clean any remaining debris from the machine and from the immediate area.

Remove top guard and inspect cutters for damage.

Clear any shredded paper from cutter area. Pull tray from lower front of

machine and empty.

11

Summary of Contents for 800-1000 Series

Page 19: ...Figure 1 SHREDDER OPERATION 19 ...

Page 20: ...Figure 2 CHAIN LUBRICATION 20 ...

Page 21: ...Figure 3 REDUCER LUBRICATION PN TA5215H40 21 ...

Page 22: ...Figure 4 CONVEYOR BELT TAKE UP 22 ...

Page 23: ...Figure 5 CHAIN SAG 23 ...

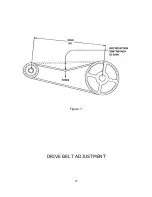

Page 25: ...Figure 7 DRIVE BELT ADJUSTMENT 25 ...

Page 35: ......