MAINTENANCE

Cleaning

ALWAYS

lock off power before cleaning, lubricating, maintaining, removal of

any guard, and after shredding operation is complete.

Daily cleaning: (After each 8 hours of operation)

o

Remove top guard

o

Remove paper buildup from cutters and combers (compressed air

(maximum 40 PSI) or vacuum may be used)

o

Visually inspect cutters for damage

o

Replace all guards

o

Remove side guard

o

Remove paper buildup from crusher area and belt pulley area

o

Replace all guards

o

Empty tray (lower front of cabinet)

Weekly cleaning: (After each 40 hours of operation)

o

Repeat all daily cleaning steps

o

Remove side guards and end guards

o

Remove paper buildup from base

o

Wipe entire machine clean being careful to observe any evidence of oil

leaks. Should leakage be observed, request the attention of the

appropriate maintenance personnel

o

Check for loose hardware on the reducer collars, the crusher paddles,

etc

o

Remove all tools, rags, solvents from machine

o

Replace all guards

12

Summary of Contents for 800-1000 Series

Page 19: ...Figure 1 SHREDDER OPERATION 19 ...

Page 20: ...Figure 2 CHAIN LUBRICATION 20 ...

Page 21: ...Figure 3 REDUCER LUBRICATION PN TA5215H40 21 ...

Page 22: ...Figure 4 CONVEYOR BELT TAKE UP 22 ...

Page 23: ...Figure 5 CHAIN SAG 23 ...

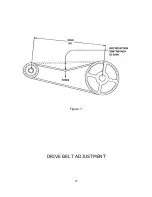

Page 25: ...Figure 7 DRIVE BELT ADJUSTMENT 25 ...

Page 35: ......