•

All rollers and pulleys must be set square with the frame before

making any belt tracking adjustments. All guards should be in

place (

except

conveyor side guards) before proceeding.

o

Mark the initial position. Make all adjustments in small increments.

•

By design, the conveyor belt should have 1/16” or less

clearance to side frames. This assists in preventing paper from

getting under the belt but some side rubbing may be expected.

This is normal.

o

Loosen jam nuts, each side of machine (see fig. 4, page 22).

o

Turn jam nuts half turn each side, repeating until belt is at proper

tension

o

Ensure all personnel are clear and that no tools are on machine or

input conveyor

o

Turn power on

o

Run machine in Forward

o

Stop machine and turn power off

o

Adjust alignment by tightening take-up bolt on side of conveyor where

belt is rubbing side frame. Tighten only one quarter turn at a time

o

Tighten jam nuts

o

Replace all guards

o

Turn power on

o

Run machine forward for five minutes. If further alignment is

required, repeat the above steps

NOTE:

Belt may run slightly off center. When machine is run in reverse, the belt

may run slightly off center to the opposite side. This is normal. The belt

may stretch during the first few days of operation. This will affect alignment

since the belt alignment relies in part on proper tensioning for effective

tracking

15

Summary of Contents for 800-1000 Series

Page 19: ...Figure 1 SHREDDER OPERATION 19 ...

Page 20: ...Figure 2 CHAIN LUBRICATION 20 ...

Page 21: ...Figure 3 REDUCER LUBRICATION PN TA5215H40 21 ...

Page 22: ...Figure 4 CONVEYOR BELT TAKE UP 22 ...

Page 23: ...Figure 5 CHAIN SAG 23 ...

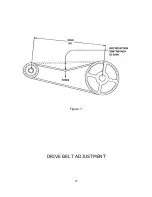

Page 25: ...Figure 7 DRIVE BELT ADJUSTMENT 25 ...

Page 35: ......