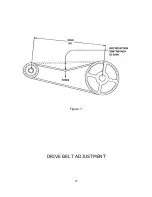

DRIVE BELT ADJUSTMENT

o

Lock power off

o

Remove guard, drive side

o

Check sheave alignment by placing a straight edge or a stretched

string across the sheave faces so that it touches all four points of

contact. Misalignment of more than one half of one degree (1/8” in

12”) may adversely affect belt life, cause belt rollover, and/or cause

internal belt damage

o

Ideal tension is the lowest tension at which the belt will not slip under

peak load conditions

o

Check tension frequently during the first 48 hours of run-in operation.

o

Over tensioning shortens belt and bearing life

o

Keep belts free of foreign material which may cause slippage

o

Make V-drive inspection on a periodic basis. Tension only when

slipping. Never apply belt dressing as this will damage the belt and

cause early failure

o

Adjust tensioning by measuring the distance between sheaves center

to center. At the midpoint between centers, apply a force

(perpendicular to the span) large enough to deflect the belt 1/64” for

each inch of span length. For example, the deflection of a 100 inch

span would be 100/64 or 1-9/16 inches. Compare this measured force

to the accompanying chart. If the force is between “normal” and

1-1/2 times “normal”, the drive tension would be satisfactory. A force

below the “normal” value indicates an under-tensioned drive. If the

force is more than 1-1/2 times “normal”, the drive is tighter than it

needs to be

Model No.

Deflection

Normal

New Belt

800-1000/15

3/8”

18.0 lbs.

27.0 lbs.

800-1000/10

3/8”

17.6 lbs.

26.4 lbs.

(See Fig. 7, page 25)

16

Summary of Contents for 800-1000 Series

Page 19: ...Figure 1 SHREDDER OPERATION 19 ...

Page 20: ...Figure 2 CHAIN LUBRICATION 20 ...

Page 21: ...Figure 3 REDUCER LUBRICATION PN TA5215H40 21 ...

Page 22: ...Figure 4 CONVEYOR BELT TAKE UP 22 ...

Page 23: ...Figure 5 CHAIN SAG 23 ...

Page 25: ...Figure 7 DRIVE BELT ADJUSTMENT 25 ...

Page 35: ......