Troubleshooting

“WARNING”

LOCK OUT POWER

before performing any cleaning, oiling,

maintenance, or trouble shooting.

PROBLEM

POSSIBLE CAUSE

SOLUTION

DEFECTIVE STOP BUTTON

CHECK CONTINUITY (NC) REPLACE

IF BAD

MACHINE WILL NOT SHUT

DOWN USING STOP

BUTTONS

CONTACTS BURNED TOGETHER IN

REVERSING CONTACTOR

CHECK EACH LEG OF FORWARD

SIDE OF CONTACTOR FOR

CONTINUITY. THERE SHOULD BE

NO CONTINUITY. IF THERE US,

CONSULT FACTORY FOR

REPLACEMENT PART.

MACHINE WILL NOT RUN

IN FORWARD OR REVERSE

IF POWER LIGHT IS ILLUMINATED,

PROCEED TO NO. 7

1) NO POWER

CHECK POWER SUPPLY

2) KEY SWITCH OFF

TURN ON

3) FUSE BLOWN

REMOVE EACH FUSE AND CHECK

FOR CONTINUITY. IF BAD, REPLACE

4)OVERLOAD TRIPPED IN

PANEL

RESET

5) CONTROL TRANSFORMER

FUSE BLOWN

REMOVE EACH FUSE AND CHECK

FOR CONTINUITY. IF BAD, REPLACE

6) STOP BUTTON STUCK "IN"

CHECK BUTTONS

7) LOOSE WIRE IN PANEL

CHECK TERMINAL STRIP FOR

DISCONNECTED OR LOOSE WIRES.

RE-CONNECT TIGHTEN TO PROPER

LOCATION ON STRIP

8) DEFECTIVE CONTACT

BLOCK ON STOP BUTTON

CHECK BLOCK FOR CONTINUITY. IF

BAD, REPLACE

ONE LEG OF THE 3-PHASE

POWER IS DEAD

REMOVE EACH FUSE AND CHECK

FOR CONTINUITY IN THE POWER

SUPPLY DISCONNECT

MOTOR HUMS OR

BUZZES, BUT WILL NOT

TURN IN EITHER

FORWARD OR REVERSE

("SINGLE PHASING")

CONTACTS BURNED IN CONTACTOR

AND NOT MAKING A CONNECTION

ON ONE LEG

CONSULT FACTORY FOR

REPLACEMENT CONTACTOR

DEFECTIVE MOTOR

CONSULT FACTORY FOR

REPLACEMENT MOTOR

26

Summary of Contents for 800-1000 Series

Page 19: ...Figure 1 SHREDDER OPERATION 19 ...

Page 20: ...Figure 2 CHAIN LUBRICATION 20 ...

Page 21: ...Figure 3 REDUCER LUBRICATION PN TA5215H40 21 ...

Page 22: ...Figure 4 CONVEYOR BELT TAKE UP 22 ...

Page 23: ...Figure 5 CHAIN SAG 23 ...

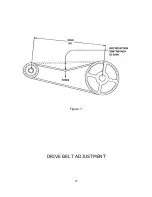

Page 25: ...Figure 7 DRIVE BELT ADJUSTMENT 25 ...

Page 35: ......