GB

8

3.5

SETTINGS

3.5.1 Setting the driving depth

Tools required:

●

1 Allen key 4 mm

(included in delivery)

If the operational pressure of the stapler cannot be set or

if the setting range is not sufficient, the driving depth can

be varied by adjusting the height-adjustable castors.

The axes of the height-adjustable castors are arranged

eccentrically on the roller bearers. By turning the roller

bearers the driving depth can be set.

Roller bearer

Height-adjustable

castor

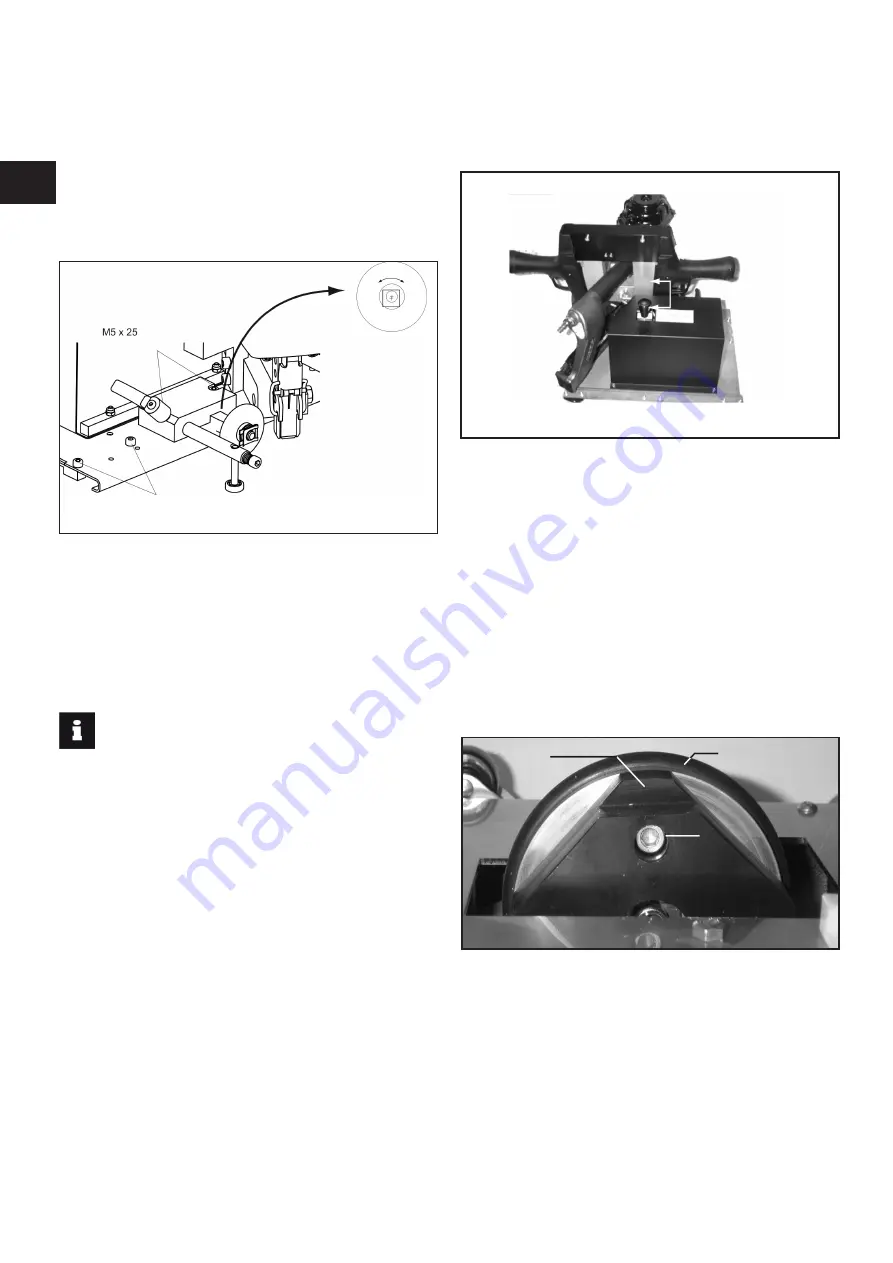

Illustration 3.5.1/1: Height-adjustable castors

Carry out the following steps:

1.

Loosen the screws M5 x 25 on both guide roller brack-

ets (see illustration 3.4.2/1) approx. 2 revolutions.

2.

Pull the roller bearers out of the guide roller brackets.

3.

Push the roller bearers back in such a way that the

castors have the desired height.

4.

Tighten the screws M5 x 25.

INFO

If the castors are in the deepest position and the driving

depth is still too low, this is due to insufficient compressed

air supply. The solution:

●

Use a more powerful compressor.

●

Shorten the compressed air supply

●

Use a supply line with a larger cross-section.

To switch the staple spacing, carry out the following steps:

1.

Tip the switch lever against the spring pressure to the

right.

2.

Swing the switch lever into the desired position.

3.

Let the switch lever snap into position using spring

pressure.

Illustration 3.5.2/1: Switching the staple spacing

wide

narrow

3.5.2 Switching the staple spacing in the direction

of movement

The staple spacing can be switched using the lever

shown in illustration 3.5.2/1 from 70 mm (narrow) to 140

mm (wide).

3.5.3 Conversion to other spacing combinations

Tools required:

●

1 Allen key 4 mm

(included in delivery)

By default, the staple spacing can be set to 70 mm and

140 mm. By exchanging the switch cam (see „accesso-

ries“) other spacing pairs can be implemented (45/90 mm

or 60/90 mm).

Illustration 3.5.3/1: Exchanging the switch cam (view from

below)

The switch cam is attached to the counter wheel with 2

screws.

To exchange the switch cam, carry out the following steps:

1.

Loosen the fastening screw shown in illustration

3.5.3/1.

2.

Turn the counter wheel by 180°.

3.

Loosen the second fastening screw, which is now

accessible.

4.

Take the switch cam off the counter wheel.

5.

To install the exchanged cam, reverse the procedure.

Counter wheel

Switch cam

Fastening screw