19

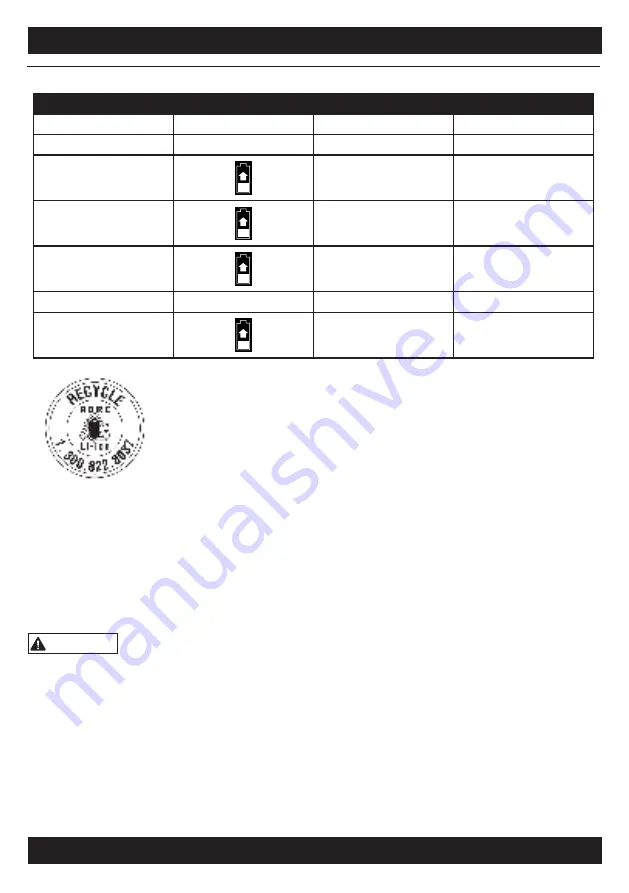

BATTERY CHARGER LABEL REFERENCE

MODE

CHARGER LABEL ICON

BATTERY PACK INSERTED? RED LIGHT/GREEN LIGHT

Standby

----

No

OFF / OFF

Evaluate

Evaluating / HOT

Yes

FLASH / OFF

Charging

Yes

ON / OFF

80% Charge

Yes

ON / FLASH

Fully Charged

Yes

OFF / ON

Maintenance

----

Yes

OFF / FLASH

Defective

Yes

FLASH / FLASH

Battery Disposal

• To preserve natural resources, please recycle or dispose of properly.

This product contains Li-Ion. Local state or federal laws may prohibit

disposal of Li-Ion batteries in ordinary trash.

• Consult your local waste authority for information regarding available

recycling and/or disposal options.

• For more information on battery recycling call 1-800-8BATTERY.

Maintenance

Read section titled “Safety Warnings” before maintaining tool.

1.

With battery removed, make daily inspection to ensure free movement of workpiece contact and

trigger.

Do not use tool if workpiece contact or trigger sticks or binds.

2.

Lubrication of the feed system is not necessary. DO NOT OIL.

3.

Wipe tool clean daily and inspect for wear, especially the workpiece contact. Replace as necessary.

WARNING

Repairs other than those described here should be performed only by trained,

qualified personnel. Contact SENCO for information at 1-800-543-4596.

Accessories

SENCO offers a full line of accessories for your SENCO tools, including:

• Battery

• Belt Hook

• Battery Charger

• Safety Glasses

For more information or a complete illustrated catalogue of SENCO accessories, ask your representative or

www.senco.com.

TOOL OPERATION

Summary of Contents for Fusion F-15XP

Page 24: ......