SAFETY WARNINGS

6

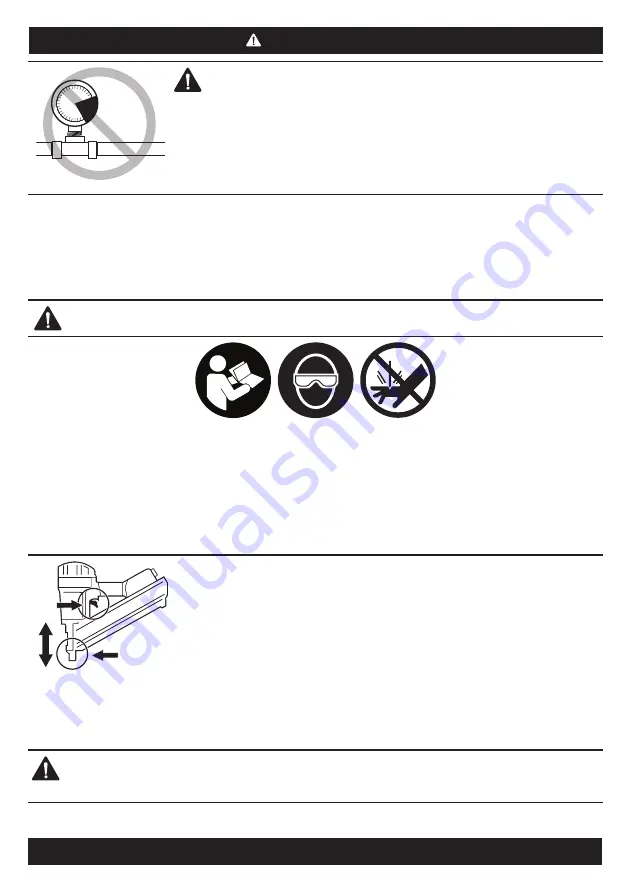

200 psig

13.7 bar

Do not connect tools to air pressure that potentially exceeds 200 psig or 13.7 bar.

Regulators shall be used to limit compressed air pressure supplied to tool.

Regulators shall be set at an operational pressure that is lower than or equal to

manufacturers specified maximum.

Air hose must have a minimum working pressure rating of 150 PSIG (10.3 bar) or

150% of the maximum pressure produced in the system, whichever is higher.

The tool and air supply hose must have a hose coupling such that all pressure is

removed from the tool when the coupling joint is disconnected.

Use extra caution when driving fasteners into existing walls or other blind areas to prevent contact with hidden objects

or persons on other side (e.g. wires, pipes, etc.).

Never use a tool that leaks air or needs repair.

Never lift, pull or lower the tool by the hose.

Keep tool pointed away from yourself and others while connecting air to the tool.

Never use any part of the tool (cap or main body) as a hammer. The tool could activate or become unsafe.

Read and understand all safety instructions.

Product Safety Messages

• Read and Understand tool labels and manual. Failure to follow warnings will result in DEATH or SERIOUS INJURY.

• Operators and others in work area MUST wear safety glasses with side shields.

• Keep fingers AWAY from trigger when not driving fasteners to avoid accidental discharge.

• Know and understand what trigger system you are using. Check manual for triggering options.

• NEVER point tool at yourself or others in work area.

• NEVER use oxygen or other bottled gases. Explosion may occur.

Maintenance

Always refer to both tool maintenance instructions below and the troubleshooting

guide in this manual to assure years of reliable service.

Make sure all screws and caps are securely tightened at all times. Make daily inspec-

tions for free movement of trigger and safety element. Never use the tool if parts are

missing or damaged.

When tool is disconnected from air, make daily inspection to assure free movement of

safety element and trigger. Do not use tool if safety element or trigger sticks or binds.

Squirt Senco pneumatic oil (5 to 10 drops) into the air inlet twice daily (depending on

frequency of tool use). Other oils may damage O-rings and other tool parts.

Wipe tool clean daily and inspect for wear. Use non-flammable cleaning solutions only

if necessary.

DO NOT SOAK

.

WARNING

Repairs other than those described here should be performed only by trained, qualified personnel. Contact

SENCO for information at 1-800-543-4596.