11

OPERATION

PRE-START CHECKLIST:

1. Remove any moisture in the air compressor air tank. Remove excessive pressure with an air tool, then open

the air tank drain valve in the bottom of the air tank. Close tightly when drained.

WARNING: Risk of bodily injury. NEVER attempt to open the drain valve when

more than 0.7 bar

of air pressure is in the air tank!

2. Make sure the air compressor Motor Switch is in the OFF (0) position.

3. Make sure all safety valves are working correctly.

4. Make sure all guards and covers are in place and securely mounted.

START-UP:

1. Ensure the lever on the pressure switch box is in the OFF (0) position.

2. Plug the power cord into a grounded outlet.

3. Move the lever on the pressure switch box to the On (1) position.

4.

AUTO OPERATION:

The ON position will allow the air compressor to START building

up pressure in the air tanks and STOP when correct pressure is achieved. When pressure drops with usage,

the air compressor will START building up pressure again.

5. Set pressure by adjusting the pressure regulator knob counterclockwise for less pressure and clockwise for

more pressure.

6. If you notice any unusual noise or vibration, stop the air compressor and refer to Troubleshooting .

SHUTDOWN:

1. To stop the air compressor, move the lever on the pressure switch box to the OFF (0) position. NEVER

stop the air compressor by unplugging it from the power source. This could result in risk of electrocution.

2. Drain air from the air tank by releasing air with an attached air tool or by pulling on the safety relief valve ring.

3. Once pressure in the air tanks register under 0.7 bar, open the drain valve under each air tank to drain any

moisture.

4. Allow the air compressor to cool down.

5. Wipe air compressor clean and store in a safe, non-freezing area.

MAINTENANCE

Read the instruction manual before performing maintenance. The following procedures must be performed when

stopping the air compressor for maintenance or service.

1. Turn off air compressor.

WARNING: Never assume the air compressor is safe to work on just because it is not

operating. It could restart at any time!

2. Disconnect cord from main power supply.

3. Open all drains.

4. Wait for the air compressor to cool before starting service.

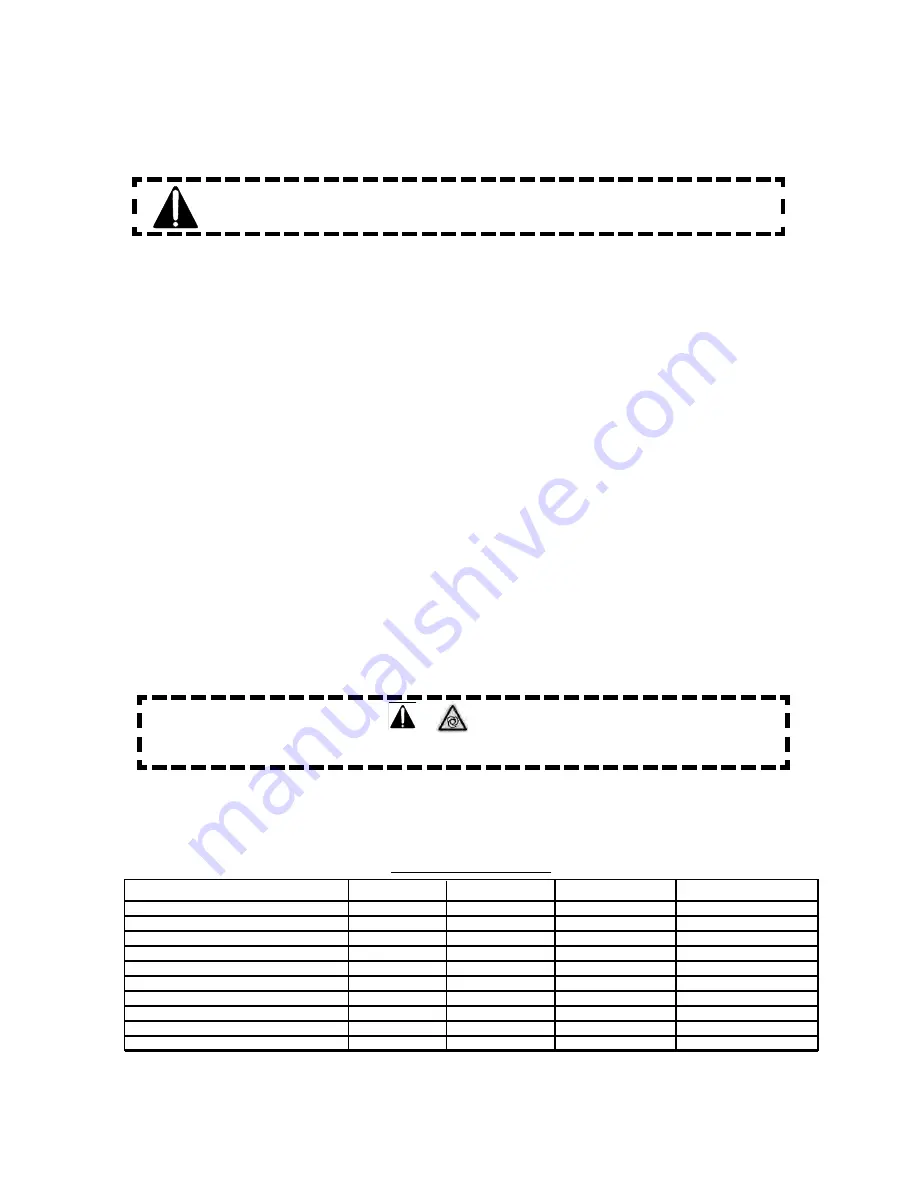

MAINTENANCE CHART

PROCEDURE

DAILY

WEEKLY

MONTHLY

200 HOURS

Check pump oil level

X

Oil leak inspection

X

Drain condensation in air tank(s)

X

Check for unusual noise/vibration

X

Check for air leaks

X

Inspect air filter

X

Clean exterior of compressor

X

Check safety relief valve

X

Change pump oil*

X

Replace air filter

X

*The pump oil must be changed after the first 50 hours of operation and every 200 hours or 3 months, whichever

comes first. Recommended non-detergent straight weights.

Summary of Contents for PC1249

Page 8: ...8...

Page 9: ...9...

Page 15: ...15 Measured sound power level dB 88 dBA 88 dBA Guaranteed sound power level dB 90 dBA 90 dBA...

Page 24: ...8...

Page 25: ...9...

Page 31: ...15 Measured sound power level dB 88 dBA 88 dBA Guaranteed sound power level dB 90 dBA 90 dBA...

Page 40: ...8...

Page 41: ...9...

Page 47: ...15 Measured sound power level dB 88 dBA 88 dBA Guaranteed sound power level dB 90 dBA 90 dBA...

Page 56: ...8...

Page 57: ......

Page 63: ...15 Measured sound power level dB 88 dBA 88 dBA Guaranteed sound power level dB 90 dBA 90 dBA...

Page 72: ...8 OMINAISUUDET KOMPRESSORI...

Page 73: ...9 OMINAISUUDET KOPRESSORI...

Page 79: ...15 Measured sound power level dB 88 dBA 88 dBA Guaranteed sound power level dB 90 dBA 90 dBA...

Page 88: ...8...

Page 89: ...9...

Page 95: ...15 Measured sound power level dB 88 dBA 88 dBA Guaranteed sound power level dB 90 dBA 90 dBA...

Page 97: ...2010 by Verpa Senco BV PC1249 PC1251 5HY PC1249 PC1251...

Page 98: ...2 3 3 3 4 4 5 5 6 6 6 7 7 7 8 10 10 10 10 11 11 11 11 11 12 14 15 16...

Page 99: ...3...

Page 100: ...4...

Page 101: ...5...

Page 102: ...6...

Page 103: ...7...

Page 104: ...8...

Page 105: ...9...

Page 106: ...10...

Page 107: ...11...

Page 108: ...12...

Page 109: ...13 PRAWDOPODOBNA PRZYCZYNA Uszkodzony zaw r wlotowy kierunkowy...

Page 110: ...14...

Page 111: ...15 Measured sound power level dB 88 dBA 88 dBA Guaranteed sound power level dB 90 dBA 90 dBA...

Page 112: ......

Page 120: ...8...

Page 121: ...9...

Page 127: ...15 Measured sound power level dB 88 dBA 88 dBA Guaranteed sound power level dB 90 dBA 90 dBA...

Page 128: ......

Page 136: ...8...

Page 137: ...9...

Page 143: ...15 Measured sound power level dB 88 dBA 88 dBA Guaranteed sound power level dB 90 dBA 90 dBA...