6

ENAMEL RATER MANUAL: V.10

1.2.1

BODY CONTACT AND LEVEL CHECKING

One of the problems the enamel rating test has suffered in the past

is that if any part of the circuit has a poor, high resistance contact

only a small current will flow and the instrument will show a bad can

as good. This is a particular problem where electrical contact is

made with the can body.

In order to overcome this problem the has special circuitry

which checks the contact with the can body and will not allow the

test to proceed until a good contact has been detected. In addition

to this, a similar circuit checks that the electrolyte level within the

can is adequate and so avoids the problem of the upper zone of

the can not being fully tested due to insufficient electrolyte. These

two circuits together will also detect a fault anywhere in the

connector or wiring to the probe, making the fail-safe in its

operation.

1.2.2

SEMI-AUTOMATIC OPERATION

Another spin-off of these check-circuits is that the can be

configured to detect a change of can and will automatically start the

test once a new can is correctly inserted. An internal timer will

freeze the reading when a preset time (e.g. 4 seconds) has elapsed

and one key press then prepares the instrument for the next can.

1.2.3

BATCH OPERATION

As the operator rates cans the will store the readings (up

to 99) in its memory as a batch. At any time during the batch

statistical information about the batch can be displayed and at the

end of the batch the readings in tabular format together with the

statistical information can be output to a printer or computer if

required.

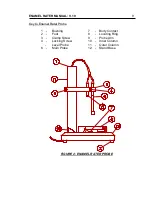

1.2.4

CONSTRUCTION

The acrylic coated steel case and waterproof polyester facia panel

are designed to ensure that the will withstand the rigours

of a factory environment. Further to this the case, mains-switch

and connectors are all sealed to I.P.65 rating, thus preventing any

ingress of corrosive electrolytes and allowing operation of the

in "hose-down" areas.