3

2.0mm SMART CLEANER Fiber Optic Cleaner

www.senko.com

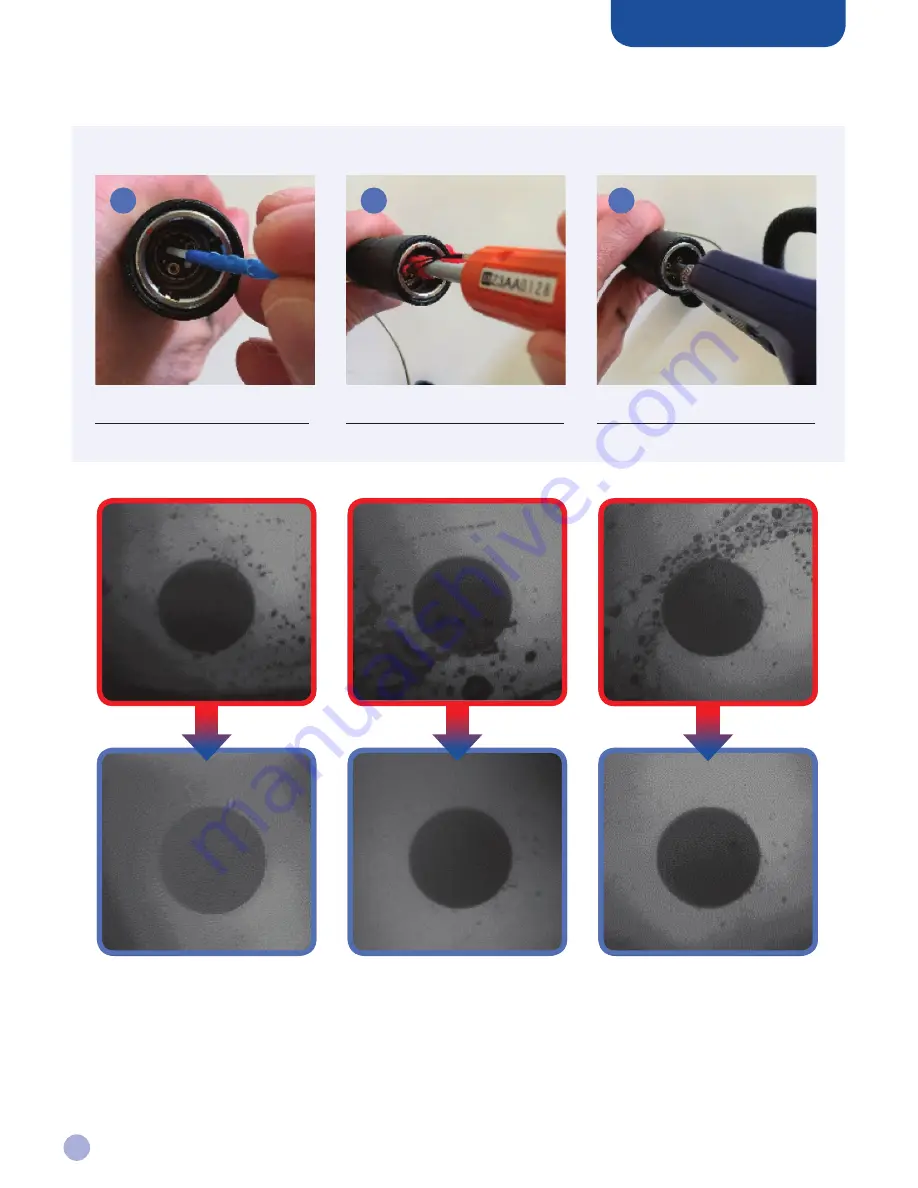

Demonstration Of Typical Cleaning Performance

After one engagement

Fine dust particles

After one engagement

Skin oil residue

After one engagement

Moisture residue

from duster

Step 1:

Apply contaminate

Step 2:

Engage cleaner one time

Step 3:

Check and record image

1

2

3

Test Setup For Cleaning Demonstration