Page 1

Copyright © 2019 Sensata Technologies, Inc.

Terminals

Maximum recommended terminal screw torque

input terminal: 5 in-lb (0.5 Nm)

Maximum recommended terminal screw torque

load terminal: 18-20 lb-in (2.0-2.2 Nm)

Recommended wire sizes as shown in TABLE 1.

Important Considerations

Be sure to use input and output voltages within

operating ranges.

LED provides status operation of the SSR, as

shown in TABLE 3

|

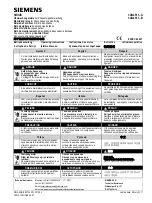

PMP SERIES

PANEL MOUNT PROPORTIONAL CONTROL SOLID STATE RELAYS

MOUNTING INSTRUCTIONS

ORDERING OPTIONS

WIRING DIAGRAM

Crydom PMP Series Solid State Relays were developed to offer precise control of the power delivered to an AC load in a standard 22.5 mm industrial package. Quick and easy installation is coupled with low drive

power requirements and efficient, reliable power SCR output. This compact new design offers up to 90 A

RMS

in ambient temperatures of 40ºC.

Be sure to visit the product series datasheet available at the Sensata website to complement this information. If you have questions or need additional information please contact Tech Support. Please read all

instructions before using your Proportional Control Solid State Relay (SSR)

INSTALLATION GUIDE

Choose one of the two mounting options and follow the instructions.

Mounting on Heat Sink

• Select adequate heat sink (see thermal derating curves in product series’

datasheet).

• Be sure to use a thermal pad or thermal compound (0.006-0.008 in layer

thickness recommended) between the SSR and the selected heat sink.

• SSR housing mounting holes have a diameter of 0.341 in (8.66 mm).

Two screws are needed to mount the SSR onto a heat sink (See fig.1).

Mounting screws are sold separately as HK8 and are suitable for all

Crydom heat sinks.

• Otherwise, recommended screw size is 8-32 (socket) using an allen

wrench (9/64 in) for the installation. Choose screw length considering

mounting surface hole depth and SSR baseplate thickness of 0.125 in

(3.2 mm).

• Before applying full torque tighten down both screws until they contact the baseplate.

• Then, tighten them to 20 lb-in (2.2 Nm) min.

• For optimal thermal performance heat sink fins should be oriented vertically to promote natural

convection airflow.

Mounting on Panel

• Locate the panel section on which the SSR will be mounted. Panel mount surface must provide

adequate heat sinking capability, uncoated, clean, flat (0.004 in/in recommended) and preferably

aluminum.

• Be sure to use a thermal pad or thermal compound (0.006-0.008 in layer thickness recommended)

between the SSR and the panel.

• SSR housing mounting slots have a diameter of 0.341 in (8.66 mm). Two screws are needed (not

included) to mount the SSR onto a panel. Mounting screws are sold separately as HK8. Otherwise,

recommended screw size is 8-32 (socket) using allen wrench (9/64 in) for the installation. Choose

screw length considering the mounting surface and that the SSR baseplate thickness is 0.125 in

(3.2 mm).

• Before applying full torque tighten down both screws until they contact the baseplate. Then, tighten

them to 20 lb-in (2.2 Nm) min.

Series

PMP

Operating Voltage

24:

90-280 VAC

48:

345-530 VAC

60:

420-600 VAC

Rated Load Current

25:

25 Amps

50:

50 Amps

90:

90 Amps

Terminal Layout

W:

Contactor Configuration (elevator screw)

Overvoltage Protection

Blank:

Not Included

P:

Included

Thermal Pad

Blank:

Not Included

H:

Included

PMP

-

24

-

25

-

W

-

P

-

H

Required for valid part number

For options only and not required for valid

part number

TABLE 1. Recommended Wire Sizes

Terminal Type

Wire Size (Solid / Stranded)

Wire Pull-Out Strength (lb)[N]

Output

2 x 20 AWG (0.75 mm

2

) [minimum]

25 [111]

2 x 10 AWG (6 mm

2

)

80 [355]

2 x 8 AWG (10 mm

2

) [maximum]

90 [400]

Input

28 AWG (0.09 mm

2

) [minimum]

2.2 [9.8]

12 AWG (3.3 mm

2

) [maximum]

22 [98]

TABLE 2. Operation Mode

(A)

Parameter Selector Switch

Mode

Function

MODE

D

E

F

C

B

A

A

Phase Angle, 0-5 VDC control

B

Phase Angle, 0-10 VDC control

C

Phase Angle, 4-20 mA control

D

Burst Fire, 0-5 VDC control

E

Burst Fire, 0-10 VDC control

F

Burst Fire, 4-20 mA control

DERATING CURVES

(D)

fig. 1

SSR mounted

on HS053 heat sink