CamCor CT and PRO Series Hardware Manual

A-3

Appendix A

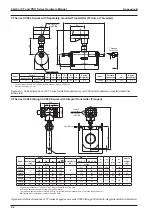

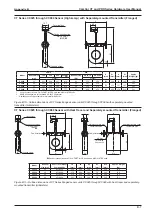

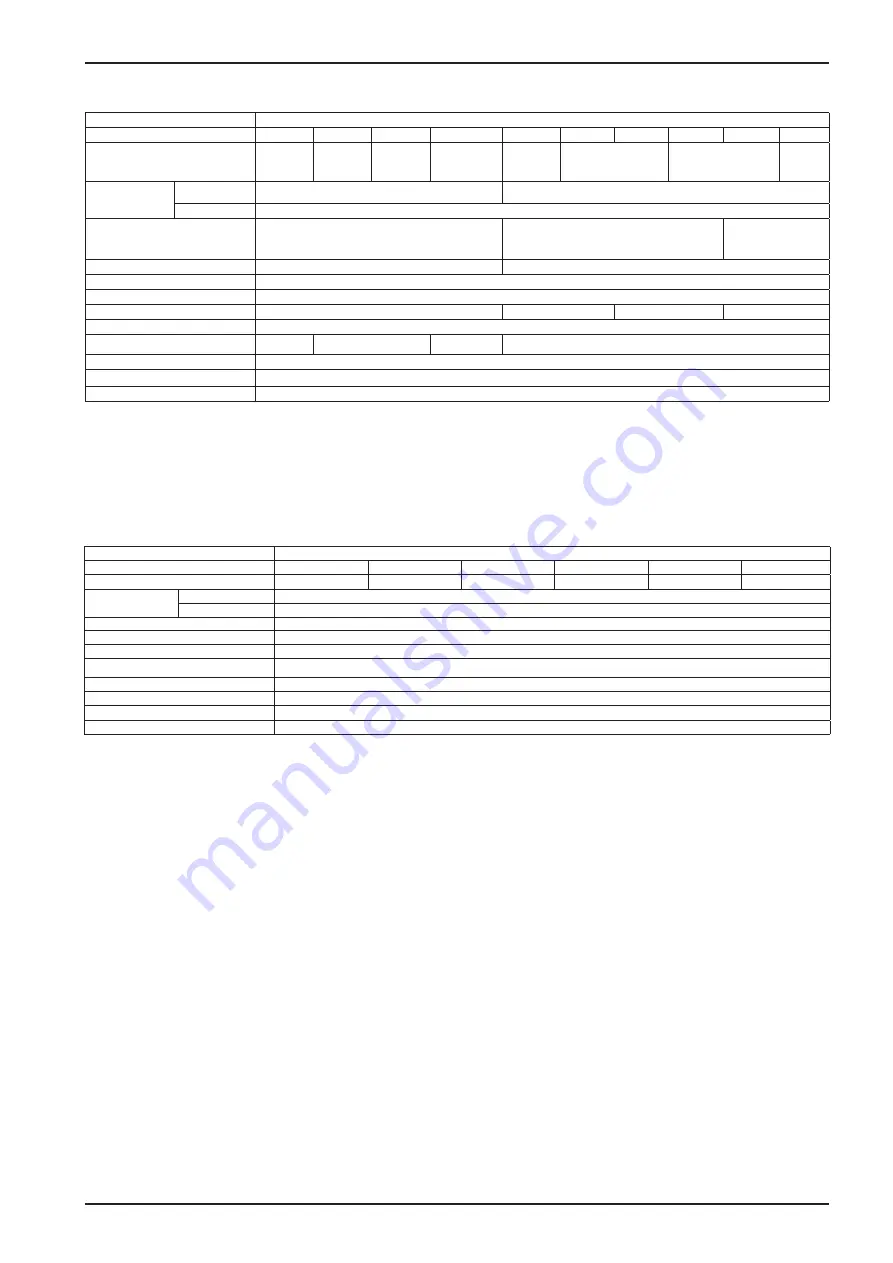

Low-Temperature Models (CC025 through CC250)

Item

Description

Model

CC025

CC040

CC050

CC080

CC100

CC150

CC15H

CC200

CC20H

CC250

Nominal size

25 mm,

1˝,

DN25

40 mm,

1-1/2˝,

DN40

50 mm,

2˝,

DN50

80 mm,

3˝,

DN80

100 mm,

4˝,

DN100

150 mm,

6˝,

DN150

200 mm,

8˝,

DN200

250 mm,

10˝,

DN250

Materials

Wetted parts

SUS316L, Alloy C22

SUS316L

Housing

SUS304

Process connection

ASME 150, 300, 600, 900

RF;

DIN PN 10, 16, 25, 40 RF

; IDF Ferrule

ASME 150, 300, 600 RF;

DIN PN 10, 16, 25, 40 RF

ASME 150, 300, RF;

DIN PN 10, 16, 25, 40

RF

Applicable fluids

Liquid and gas

Liquid

Density range

0.3 to 2.0 g/mL

Temperature range

–200°C to 50°C (separately-mounted only)

Tube withstand @ 37.8

°

C

10.5 MPa

13.3 MPa

10.7 MPa

9.0 MPa

Maximum operating pressure

Dependent on flange rating

Sensor housing withstand

1.6 MPa

1.8 MPa

1.4 MPa

—

Flow direction

Bidirectional

Explosion-proof configuration

CSA, ATEX, and IECEx (Refer to

Section 10—Explosion-proof Specifications, page 113

Dust-tight, waterproof configuration

IP66/67

1. When the SUS316L is selected as wetted parts material, the flange material will be SUS316.

2. ASME 900 flanges are only available in Alloy C22 materail.

3. DIN flanges are only available for meter material SUS316L.

4. For application with foods, this product does not comply with CE marking.

5. This pressure does not represent the rated test pressure of a pressure vessel, but 1/4 of the factory-tested breakdown pressure or the data obtained from FEA analysis,

whichever is lower. Distorted enclosures do not constitute a failure of the test.

• Only available with separately-mounted transmitter and interconnect cable (ordered separately; 10-meter minimum, available in 5-meter increments thereafter).

• For products conforming to the high-pressure gas safety regulations and CE marking, consult Cameron.

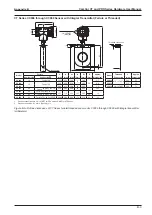

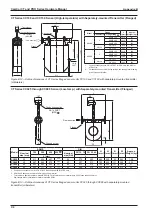

PRO SERIES SENSOR GENERAL SPECIFICATIONS

Item

Description

Model

CP006

CP010

CP015

CP025

CP040

CP050

Nominal size (mm)

10

15

15

25

40

50

Materials

Wetted parts

SUS316L

Housing

SUS304

Process connection

ASME 150, 300, 600RF, IDF Ferrule; Threaded (CP006, CP010 and CP015 only)

Applicable fluid

Liquid

Density range

0.3 to 2.0 g/mL

Temperature range

–40°C to 125°C

Maximum operating pressure

Dependent on process connection

Flow direction

Bidirectional

Explosion-proof configuration

CSA, ATEX, and IECEx (Refer to

Section 10—Explosion-proof Specifications, page 113

Dust-tight, waterproof configuration

IP66/67

1. Refer to

Section 10—Explosion-proof Specifications, page 113

. In case of non-explosion-proof model, up to 125˚C is permitted. However, the product must be used within

the maximum ambient temperature of 45˚C.

2. Cleaning in place (CIP) is permitted within the temperature range.

Summary of Contents for CamCor CC001

Page 14: ...14 CamCor CT and PRO Series Hardware Manual Section 3 This page is left blank intentionally ...

Page 24: ...24 CamCor CT and PRO Series Hardware Manual Section 3 This page is left blank intentionally ...

Page 54: ...54 CamCor CT and PRO Series Hardware Manual Section 5 This page is left blank intentionally ...

Page 62: ...62 CamCor CT and PRO Series Hardware Manual Section 7 This page is left blank intentionally ...