48

CamCor CT and PRO Series Hardware Manual

Section 5

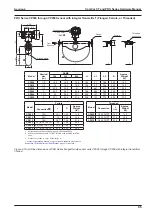

Note

Vibrating copper tubing caused by the flow meter in operation can produce zero shifts. Increase the number of fixed points

to reduce vibration.

To minimize transmission of oscillation to the sensor, the spirally wound copper tubing should start and end at the manifold

of flanged sensor housing.

Sudden temperature change may damage the performance of the flow meter. Keep the temperature change of the fluid

within ±53.6°F/min. for both heating and cooling.

CAUTION

Do not use electric heaters which could produce noise. If ambient temperature around the transmitter is expected

to exceed 131°F, a separately-mounted transmitter is recommended.

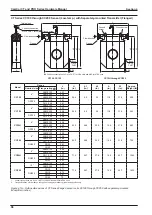

Copper

tubing

Copper

tubing

Spot

weld

Piping

Steam

Pipe retainer

(material SUS316L strip)

CC00A, CC001

CC003

Sensor unit

Sensor

unit

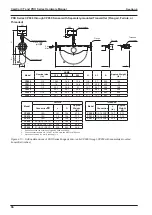

Figure 5.17—Heat and cold retention via copper tubing and pipe retainers (CT Series CC00A, CC001, and CC003 meters)

Do not apply heat retention to

terminal box and mounting tube.

Apply heat retention

only to the main body.

0.79 in.

minimum

Spot

weld

Piping

Pipe retainer

(material SUS316L strip)

Manifold

Manifold

Copper

tubing

Transmitter

CC006 through CC080

CC025 through CC080

High- and Low-temperature Models

Sensor unit

Figure 5.18—Heat and cold retention via copper tubing and pipe retainers (CT Series CC006 to CC080 meters)

Summary of Contents for CamCor CC001

Page 14: ...14 CamCor CT and PRO Series Hardware Manual Section 3 This page is left blank intentionally ...

Page 24: ...24 CamCor CT and PRO Series Hardware Manual Section 3 This page is left blank intentionally ...

Page 54: ...54 CamCor CT and PRO Series Hardware Manual Section 5 This page is left blank intentionally ...

Page 62: ...62 CamCor CT and PRO Series Hardware Manual Section 7 This page is left blank intentionally ...