20

OPERATION AND USE TIPS

S

HAPE OF THE

D

ETECTION

B

EAM AND

L

INE OF

S

IGHT

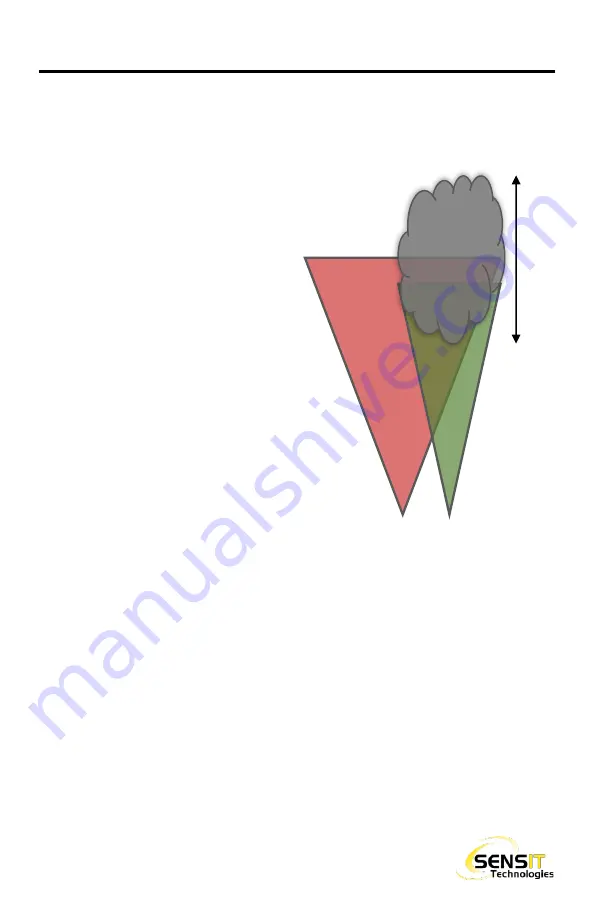

Another thing to consider is that the size of the beam can affect the reading

that the instrument gives, depending on the size of the plume.

Consider the picture to the right: the

green colored beam is roughly the

same size as the plume of gas, which

means that the instrument will be

reading only that plume. In the case

of the red beam, only half of it is

traveling through the plume, meaning

that the result on-screen is going to be

lower because part of what is being

analyzed is gas-free air.

What this means is that the distance

between the operator and the plume

can potentially affect the reading,

because the beam expands with

distance. Realistically, though, it is

unlikely to cause a noticeable effect

due to the gas plume naturally

dispersing over a (relatively) large

area. Where this might be more

noticeable is if the operator is far away

from a very small pinpoint leak. Most

of the beam will not be hitting the

plume, and will lower the reading.

In a real-

world scenario, a gas plume doesn’t have strictly defined edges like

this, and the operator obviousl

y won’t be aware of where it is to begin with.

However, what this illustrates is that technology of this nature makes it near-

impossible to get true quantitative results. There are simply too many

variables. Qualitative investigation and pinpointing is where it shines.

800

PPM

~400

PPM•M

800

PPM•M

1

M

E

T

E

R

Summary of Contents for GAS-TRAC LZ-30

Page 33: ...33 NOTES ...

Page 34: ...34 NOTES ...