FiberPatrol configurations

FiberPatrol Site Planning & Installation Guide

Page 17

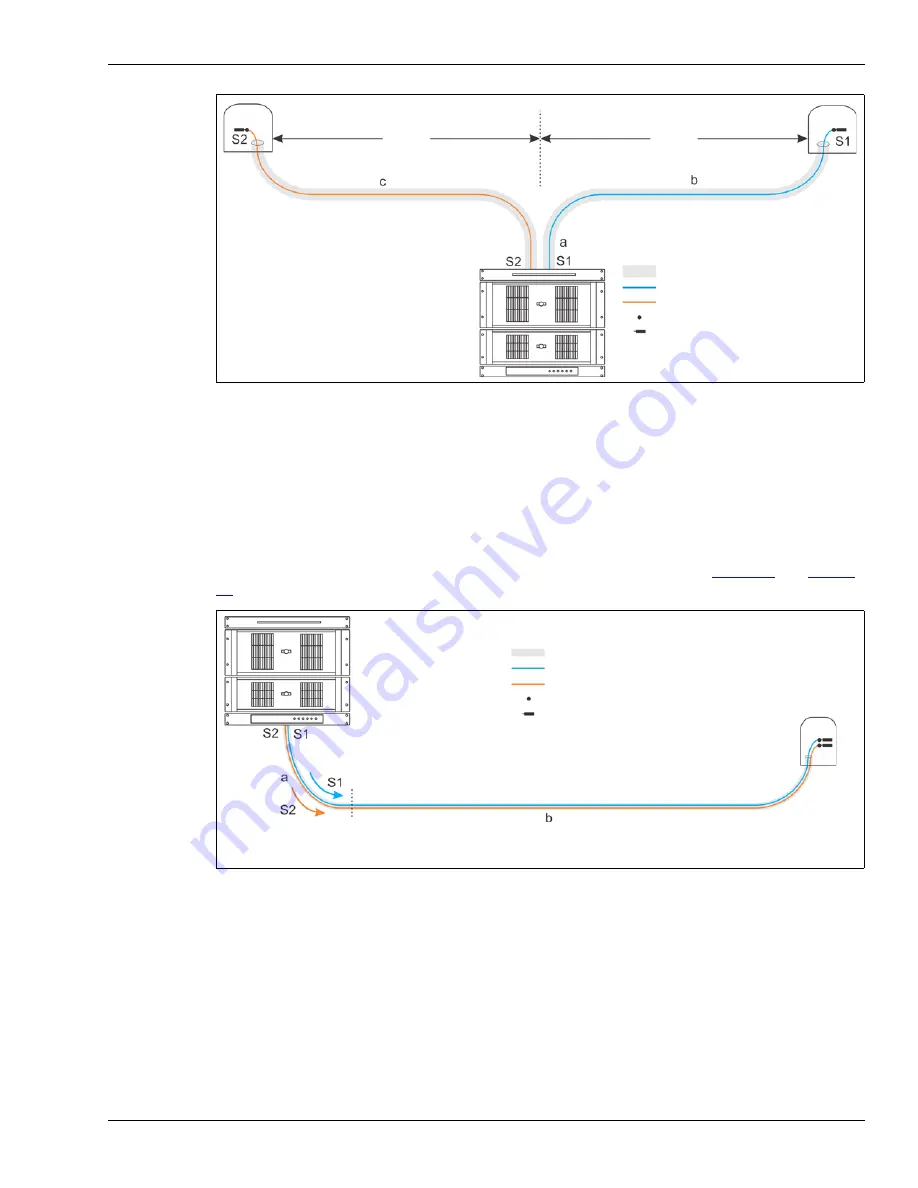

Line configurations

The line configuration is typically used when the sensor unit equipment is located at one end of the

protected perimeter, and the perimeter extends away from the equipment room in one direction.

The line configuration does not provide single cut redundancy for the full length of the sensor

cable. In the event of a cut or severely damaged sensor cable, detection will continue between the

start of the detecting sensor cable and the cut/damaged point in the cable.

illustrate the line configuration.

If necessary, the non-detecting lead cable can be spliced to the detecting cable at the start point of

the sensor cable. Splices may also be required for other site specific features.

Figure 15 FiberPatrol split configuration (2 lead cables)

Figure 16 Recommended line configuration

fiber optic cable

Note:

S1

S2

fusion splice

fiber optic termination

splice enclosure

sensor unit equipment

Cable length = 2a + b + c

single end module

splice enclosure

single end module

includes dual start module

25 km

(max.)

25 km

(max.)

fiber optic cable (sensor cable/lead cable)

S1 (sensor fiber 1 - internal to fiber optic cable)

S2 (sensor fiber 2 - internal to fiber optic cable)

fusion splice

fiber optic termination

splice enclosure

sensor unit

equipment

beginning of detecting cable

non-detecting lead cable

NOTES: Splices may be required at the beginning of the detecting cable and at other site specific features,

due to installation constraints and conditions.

Cable length = a + b