Installation on fences

Page 52

FiberPatrol FP1150 Product Guide

4.

At each point in the installation where extra cable is required, lay out a sufficient amount of

cable in a figure 8 pattern to cover the feature. If you are pulling the cable around the

perimeter, you must pull back a sufficient amount of cable after the cable is dispensed to cover

the cable length requirement for each feature.

5.

Once you have reached the end of the cable reel, leave enough cable to make a 10 m service

loop for the splice (or for fiber termination).

6.

If the installation extends past the end of this cable reel, leave enough cable to make a 10 m

service loop for the splice, and continue deploying the sensor cable.

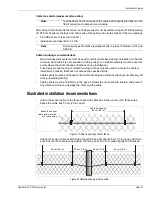

Attaching the sensor cable to the fence

FiberPatrol sensor cable is attached to the fence fabric with stainless steel cable ties.

is

an overview of the recommended cable attachment procedure.

•

Install the sensor cable on the secure side of the fence (the side opposite the threat).

•

Keep the sensor cable straight and taut while attaching it to the fence fabric.

•

Attach the cable to the fence fabric at the junction of two fence wires.

•

The recommended spacing between cable ties is 50 cm (20 in.).

•

Attach the sensor cable at both sides of each fence post approximately 25 cm (10 in.) away

from the post.

1.

Beginning at the start point post, attach the sensor cable to the fence at the junction of two

fence wires at the specified height above ground (point a).

2.

Hold the cable straight and level just past the second post and attach it to the fence at the

junction of two fence wires app. 25 cm away from the second post (point b).

3.

Attach the sensor cable at the junction of two fence wires app. 50 cm past point b (point c).

4.

Attach the sensor cable at the junction of two fence wires app. 25 cm before the second post

(point d).

5.

Attach the sensor cable at 50 cm intervals on the first fence panel (points e, f, g).

6.

Hold the cable straight and level just past the third post and attach it to the fence at the

junction of two fence wires app. 25 cm away from the third post (point h).

7.

Attach the sensor cable at the junction of two fence wires app. 50 cm past point h (point i).

Figure 60 Cable installation procedure

second post

start point post

fence-mounted

third post

conduit to sensor unit

isolation loop