FP400 Product Guide

Page 15

2

Site planning

FP400 configurations

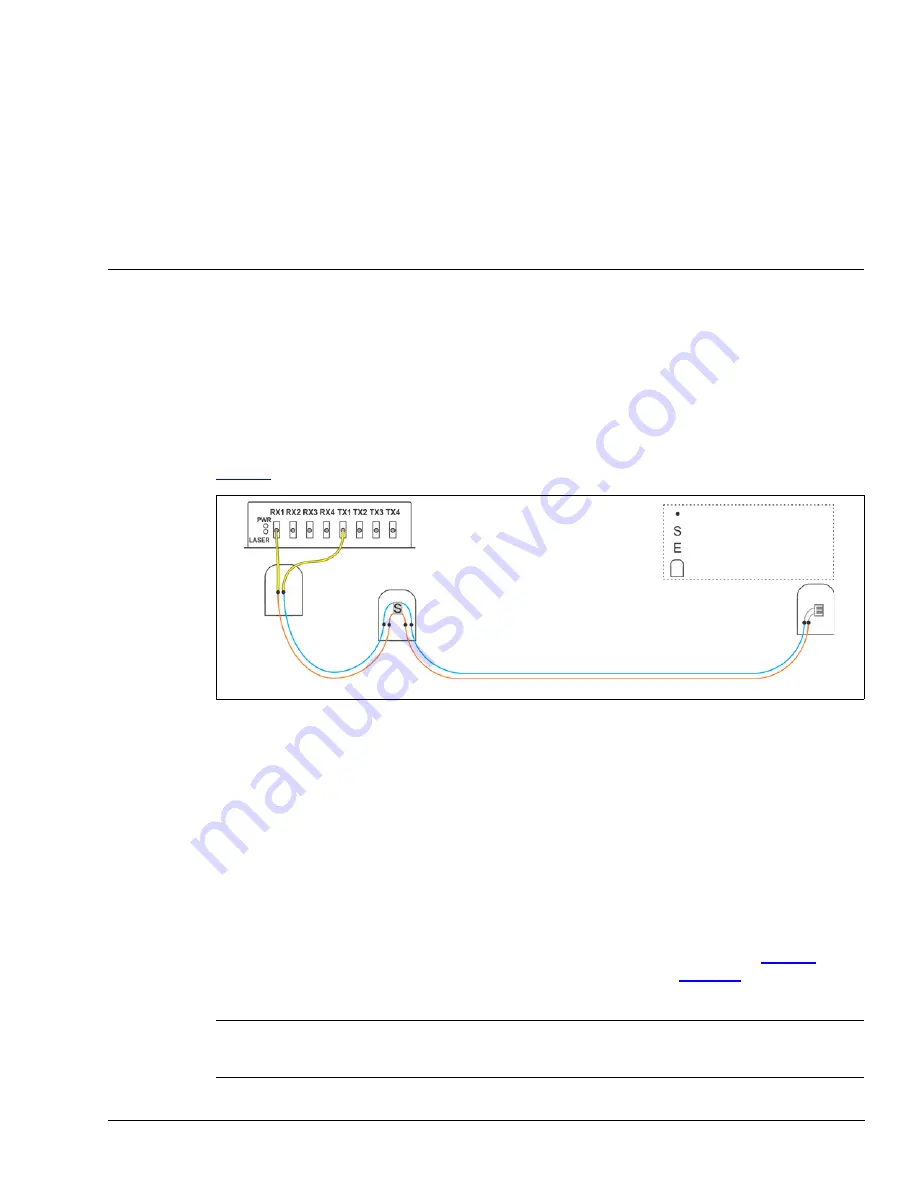

The recommended method for installing the sensor cable is to use the minimum number of splices

possible for each sensor zone. This includes 2 splices for the lead-in cable connections to the

processor, 4 splices for the start module, and 2 splices for the end module. Midspan access

techniques are recommended for non-spliced (expressed) fibers passing through an enclosure.

illustrates an FP400 sensor zone with the minimum 8 fusion splices.

The FP400 detection zone runs between the start module and end module, and can include up to

300 m of sensor cable. For planning purposes approximately 15% extra cable should be budgeted

for splice point service loops and installation variations. The 15% overage allows one sensor zone

to protect approximately 255 m (840 ft.) of perimeter fence. For longer perimeters, the 4 zones can

be installed back to back thereby extending coverage to a maximum length of 1.2 km (0.75 mi.) of

sensor cable. Four contiguous zones of sensor cable can cover approximately 1 km (0.62 mi.) of

fence. The coverage length can be extended indefinitely by networking multiple FP400 sensors

back to back.

Some FP400 zone configurations require only 2 dedicated fibers. For those configurations there is

no need to express the 10 unused fibers through the enclosure. In this situation, it is acceptable to

cut the sensor cable and splice only the required fibers. In the example drawings in

b require expressed fibers but c does not. In the example drawings in

, a requires

expressed fibers but b and c do not.

Figure 8 Single zone linear configuration (minimum splices)

Note

Expressing fibers through splice enclosures reduces the number of

fusion splices required in the field, and helps to keep the signal loss to a

minimum.

FP400 processor

up to 20 km (12.4 mi.) of lead-in cable

max. detecting cable = 300 m (984 ft.)

fusion splice

start module

end module

splice enclosure

detection

start point

detection

end point

non-detecting

Zone 1