Installing the sensor cable

Page 16

FlexPI Product Guide

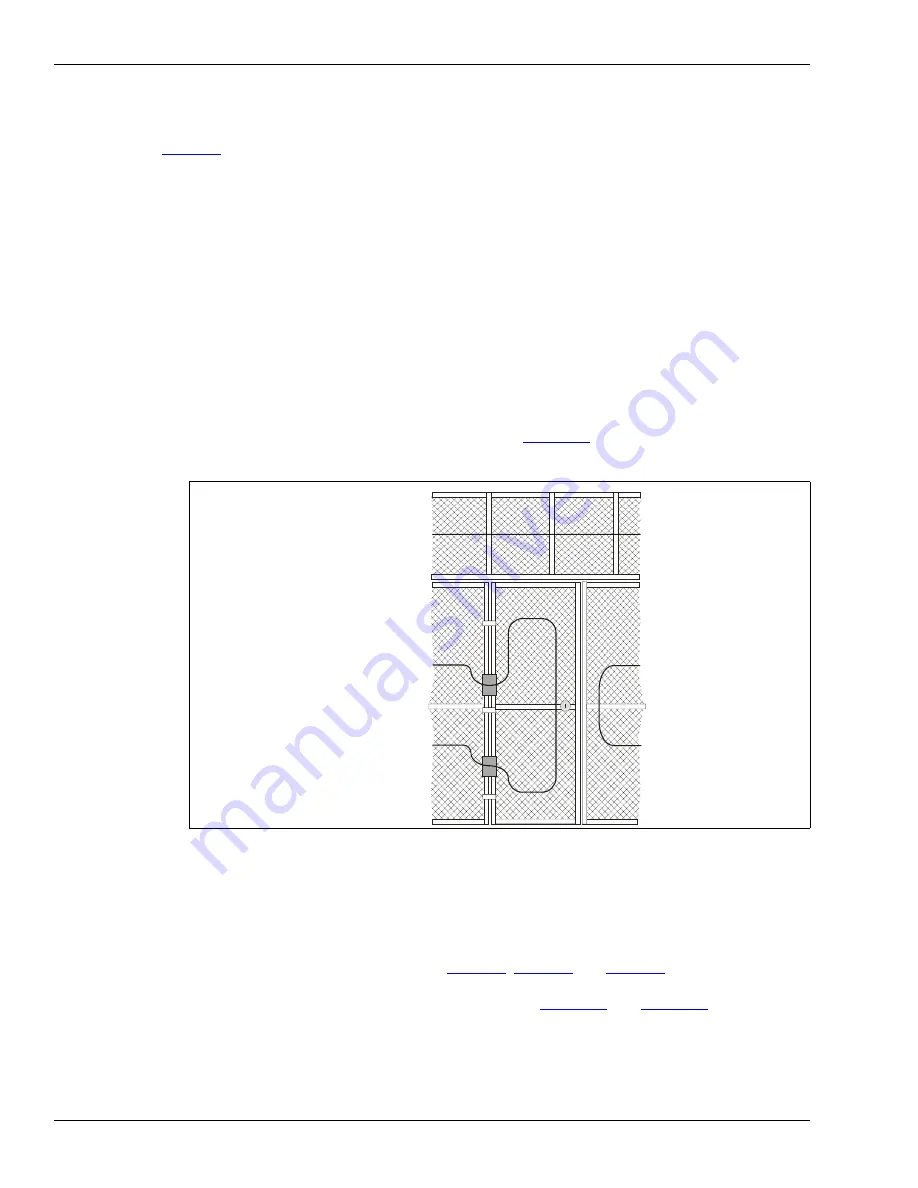

Installing cable on security cages

shows a double cable pass installation on a 3 m (10 ft.) security cage.

•

Use nylon cable ties spaced about 30 cm (12 in.) apart to attach the FlexPI sensor cable to the

security cage.

•

Attach the cable ties to the center of each fence link (not at the junctions).

•

Pull the cable ties until they are hand tight and the cable is snug to the fence.

•

Attach the sensor cable to the secure side of the cage (the side opposite the threat).

•

Space the sensor wire evenly on the security cage.

•

The recommended separation between cable passes on security cages is 1 m (3.3 ft.).

•

Create 30 cm loops at support posts for increased sensitivity.

•

To install sensor cable on security cage doors or gates, run the cable from the cage to the door

at the hinged side of the door. Ensure that there is enough slack in the cable to allow the door

to fully open and close. Ensure that the cable cannot be caught and pinched when the door

closes. Run the cable once completely around the door between 15 and 30 cm from the edge

of the door. Run the cable from the door back to the cage at the hinged side of the door.

Continue installing the cable on the security cage.

illustrates sensor cable

installation on a security cage door.

Installing cable on walls

The cable spacing depends on the type of building material and the required level of security. The

maximum recommended spacing for any type of wall surface is 1.25 m (4 ft.). The minimum

recommended spacing is 30 cm (1 ft.) (see

and

). When attaching the

sensor cable to the mounting surface use fasteners that hold the cable firmly against the surface

and space the fasteners approximately 30 cm apart (see

and

).

•

Begin at the processor location, or if using lead-in cable, at the designated start point of the

zone, and attach the cable to the wall. Leave 0.5 m (20 in.) of sensor cable at the start point, to

make the connection.

•

Run the cable along the surface parallel to the floor, using a fastener every 30 cm (1 ft.).

Figure 16: Installing sensor cable on cage doors and gates

use a sheet of rubber to

prevent the cable from being

caught or pinched when

the door opens or closes

install sensor cable along

the top section of the cage

continue the cable run on

the other side of the door

run the sensor cable

around the door app.

30 cm from the edge

run the cable from the cage

to the door on the hinged

side of the door

(if necessary)