FlexZone Product Guide

Page 97

b

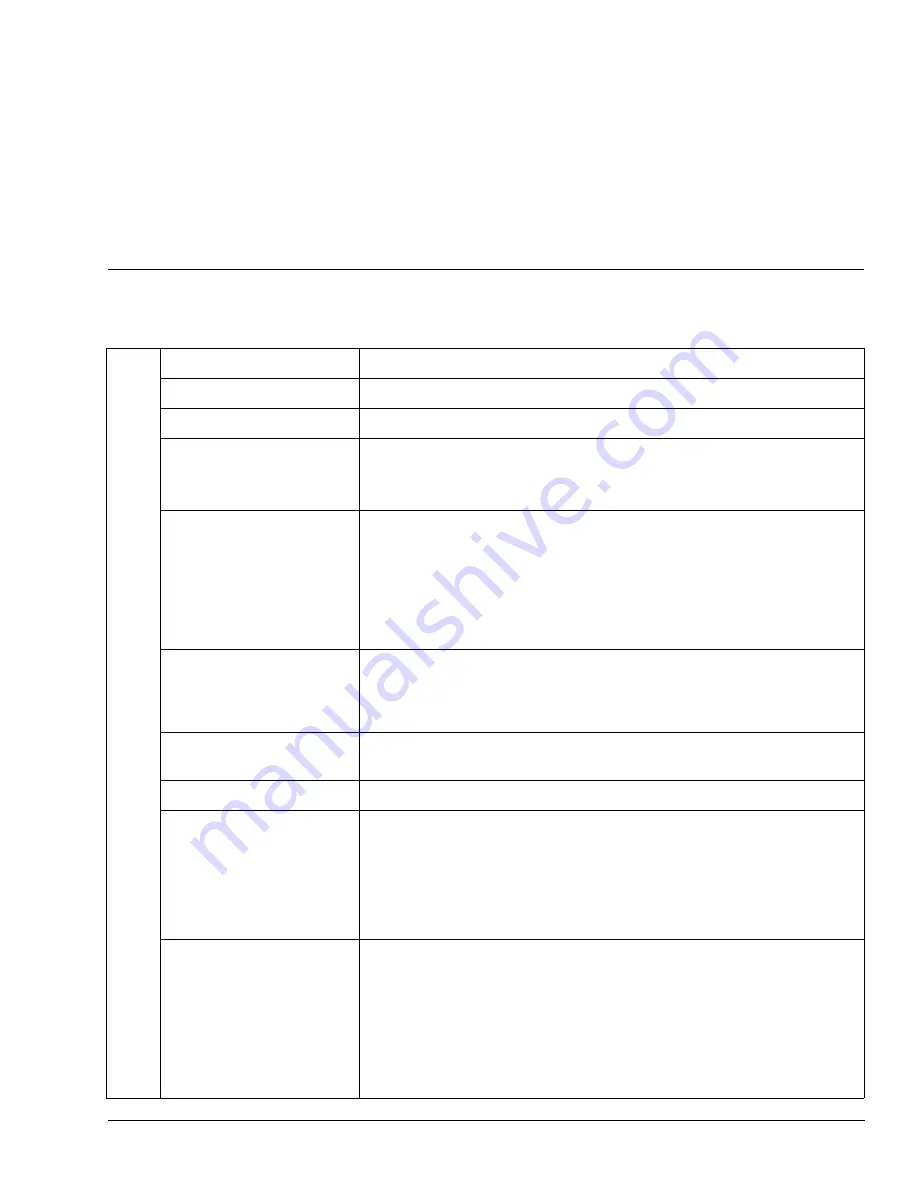

Specifications

Processor

Model

•

processor card and enclosure

PCB dimensions (L x W)

•

13.2 x 14.5 cm (5.2 x 5.7 in.)

Quantity

•

one processor per two sensor cables

Enclosure

•

IP66/NEMA 4 painted aluminum, outdoor rated

•

L x W x D 26 cm (+2.5 for cable glands) x 16 cm x 9 cm

10.25 in. (+1 for cable glands) x 6.3 in. x 3.5 in.

Cable entry ports

•

4 small cable ports (17 mm, 0.67 in.) fitted with 9.5 mm (3/8 in.)

compression glands: cable range: 2.9 - 7.9 mm (0.115 to 0.312 in.)

•

1 large cable port (22.2 mm, 0.875 in.) fitted with compression gland:

cable range: 4.3 - 11.4 mm (0.17 to 0.45 in.)

•

for armored cable, the 2 right side small cable ports must be drilled out

to accommodate 1/2 in. cable glands (22.2 mm, 0.875 in.)

Probability of detection

•

95% with a 95% confidence factor for cutting the fence, lifting the fence

fabric, or climbing over the fence unaided (based on a high quality

chain link fence, and following manufacturers’ installation and

calibration recommendations)

Maximum sensor cable

length

•

300 m (984 ft.) max. cable length - app. 10% less for linear fence

coverage - 270 m (886 ft.)

Power consumption

•

2.0 W nominal; 2.5 W nominal with NIC and option card

Power input

•

12 to 48 VDC (nominal)

•

absolute minimum 10 VDC

•

absolute maximum 60 VDC

•

min. 38 VDC input required for power over sensor cables and auxiliary

power output capability

Connectors

•

removable terminal block for power input

•

removable terminal block for relay output connections

•

removable terminal block for auxiliary input/self-test connections

•

removable terminal block for sensor cable input

•

USB port for UCM connection

•

20-pin socket for network interface card

•

micro SD card slot to record sensor response data to removable media