19

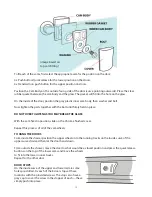

SHOWER VALVE

The shower valve can be accessed from the rear of

the shower and is located on the central tower.

The valve is divided into three parts that are joined

together.

The uppermost part is the divertor. There are

three connections able to be made here. One to

the overhead shower from the outlet pointing

upwards, another to connect to the body jets and

the third connects to the hand shower/riser bar

water inlet.

When making the connections,

ensure they are water tight. Check

all pre-fi tted hoses as these may

only be hand tight during

manufacture.

The middle part of the valve handles the water on

and off . There are no connections to be made here.

The lower part of the valve has three connections

to be made. The HOT and COLD water supplies

from you property connect to the outermost

connections - ENSURE THE FEEDS ARE THE

CORRECT WAY ROUND.

REMOVE THE WHITE PLASTIC BOX SECTION THAT

MAY BE COVERING THE VALVE ACCESS AT THE

REAR - THIS IS FOR TRANSPORT PURPOSES ONLY

AND IS NO LONGER NEEDED.

Summary of Contents for Pure Range

Page 2: ......

Page 30: ...FOR TECHNICAL ASSISTANCE PLEASE CALL 0871 526 5926 ...