Checking a SenTec TC Sensor

Check the condition of the sensor membrane and the integrity

of the sensor before and after each use and after changing the

membrane (p.

17

)!

Ensure that the sensor is clean before visually checking it. If

necessary, carefully wipe off any residue from the sensor’s

surface (including membrane, housing and cable) with 70%

isopropanol or another approved cleaning agent (refer to

sensor’s Directions for Use).

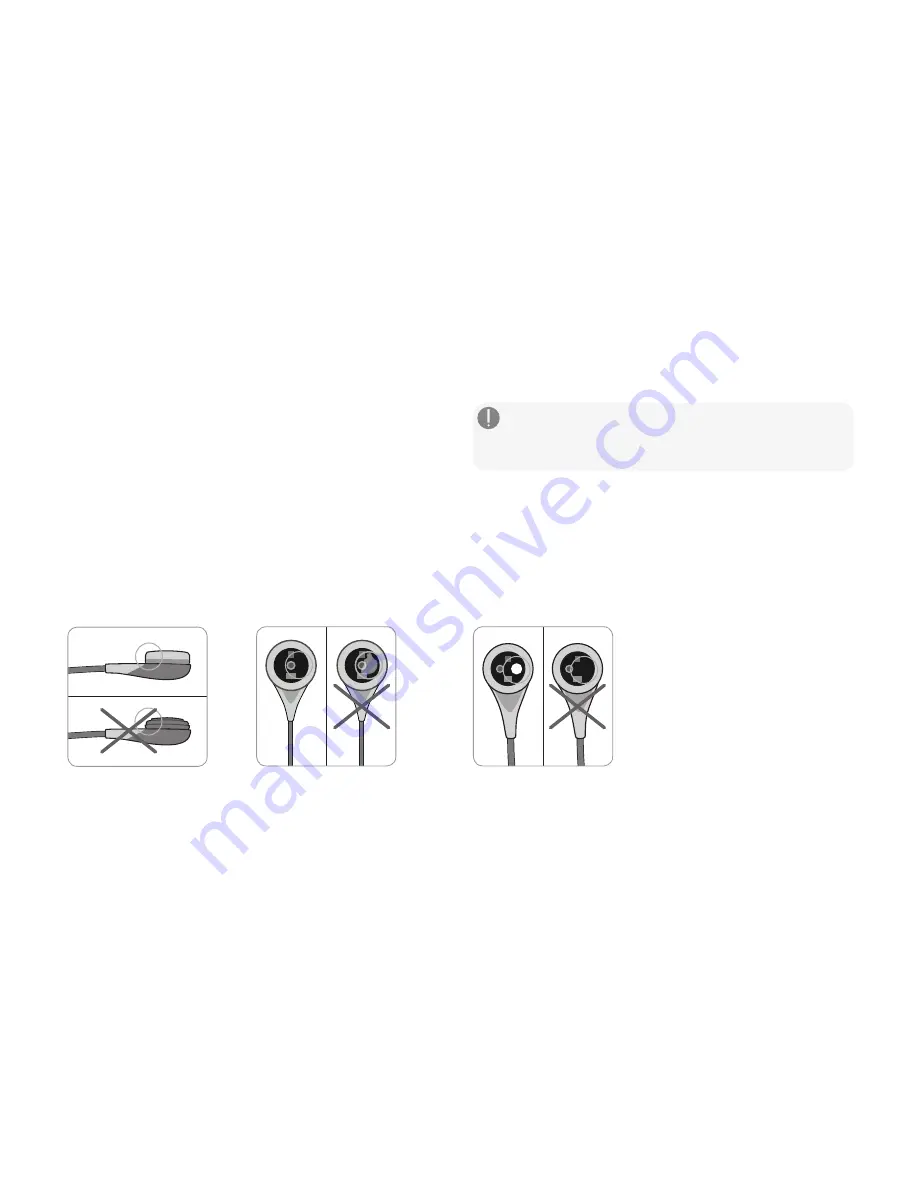

a) Change the sensor membrane if it is damaged or missing,

has a loose fit, or if there is trapped air or dry electrolyte under

the membrane.

Page 15

.

Sensor Check, Sensor Calibration/Storage and Membrane Change

CAUTION: Do not touch the delicate optical/glass

components embedded in the sensor’s surface should the

membrane be missing.

b) Do not use the sensor if there is any visible damage to

the sensor housing or cable, if the color of the ring around the

glass electrode has a metallic luster (should be brown), or if the

sensor’s red LED does not light when the sensor is connected

to the SDM. Instead, contact qualified service personnel or

your local SenTec representative regarding continued use or

replacement of the sensor.

c) When operating with an OxiVenT™

Sensor, do not use the sensor if

the off-centered, white, round spot

on the sensor surface is missing

or is not illuminated in green-cyan

color when the OxiVenT™ Sensor is

connected to the SDM with enabled

PO

2

measurement function.

Sensor Check, Sensor Calibration/Storage and Membrane

Change