SENTINEL SOLARFLUSH

7. Open tank lid to ensure the circulation

of the air.

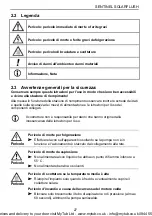

Caution

: Monitor fluid level in the tank and,

if necessary, refill heat transfer fluid to

prevent air entering the solar circuit.

8. Flush the solar circuit with the fluid.

Check at the inspection window of the

filter or through the tank opening if there

are still air bubbles in the heat transfer

fluid. Continue flushing until there is no

air remaining in the fluid.

5. End of operation

After filling and flushing the solar system

>

Switch off pump.

>

Close fill and vent valve at the solar station.

>

Open stop valve between fill and vent valve.

The pressure that is generated between pump outlet and fill valve when flushing the

pipe can be released by opening the filter at the pump inlet. It will be easier then to

unscrew the filling hose from the fill valve.

Caution:

Collect escaping pumped media in a container.

>

Unscrew the filter casing and flush remaining liquid.

>

Unscrew the filling hose from the fill valve.

>

Unscrew return hose from vent valve.

>

Screw open hose ends together with the provided connecting piece in order to

avoid dripping or escaping of fluid during transport.

14

For latest prices and delivery to your door visit MyTub Ltd - www.mytub.co.uk - info@mytub.co.uk 0844 556 1818