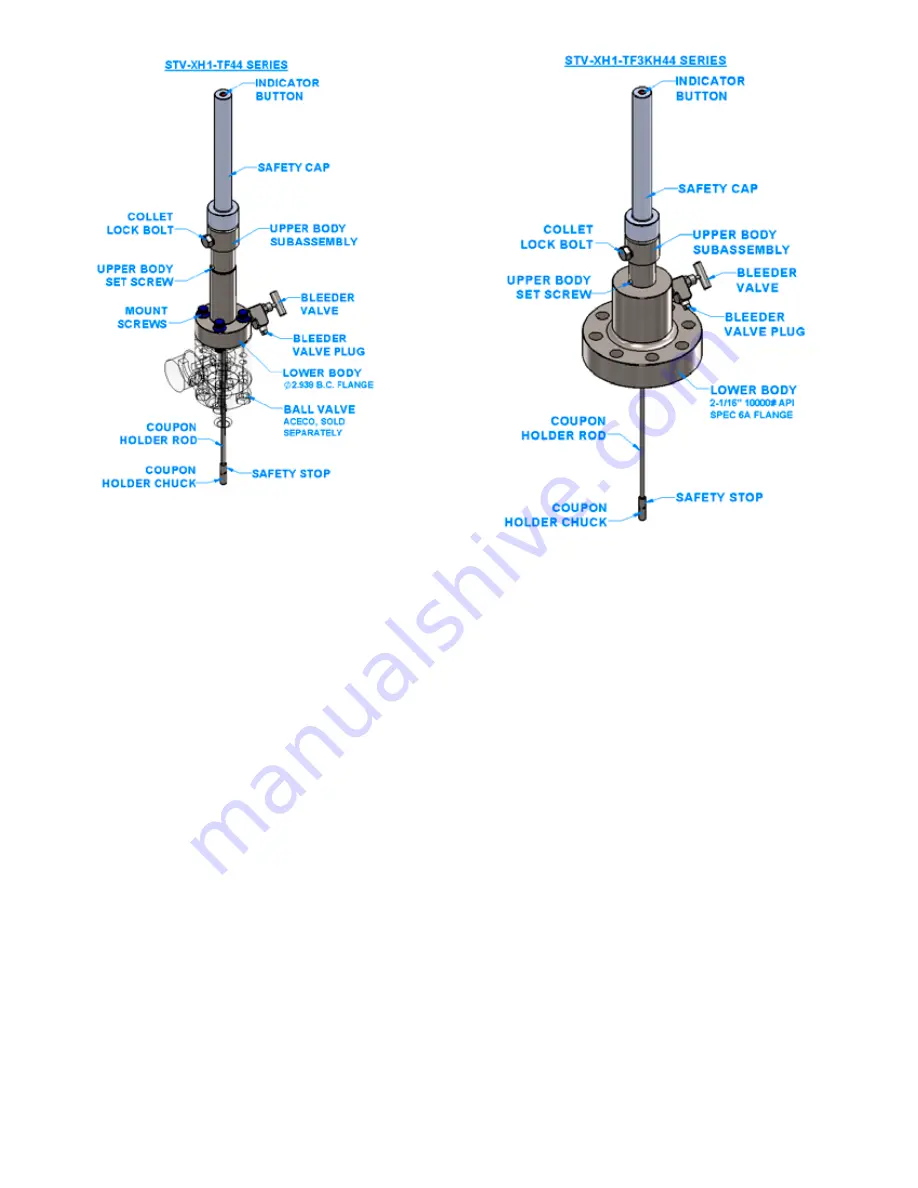

Saf-T-Vise STV-XH1 7

Installation

Prior to installing the STV-XH1, ensure that the sealing surfaces are cleaned and free of debris . Then, place the

appropriate seal or ring joint on the mating flange .

With the coupon holder rod inserted through the body, place the STV-XH1 up against the mating flange . Install the

flange bolts, tightening them down in a star pattern .

For the Aceco flange version (STV-XH1-TF44), it is recommended to use the indicated 12-Point flange head cap screws

as these are the only standard screws with a head diameter small enough to not interfere with the lower body .

The API flange version (STV-XH1-TF3KH44) can accommodate hex bolts without interference issues . Insertion and

retraction of the rod under pressure requires use of the retractor tool, the STV-T4-XH1 . Information on initial setup can

be found in the Saf-T-Vise STV-T Series Insertion Tools manual .

Operation

This tool is designed to work with the STV-T4-XH1 retraction tool . Details on the insertion and retraction operation of

this product can be found in the IOM for the STV-T series .