As per 06/2016

11

GmbH

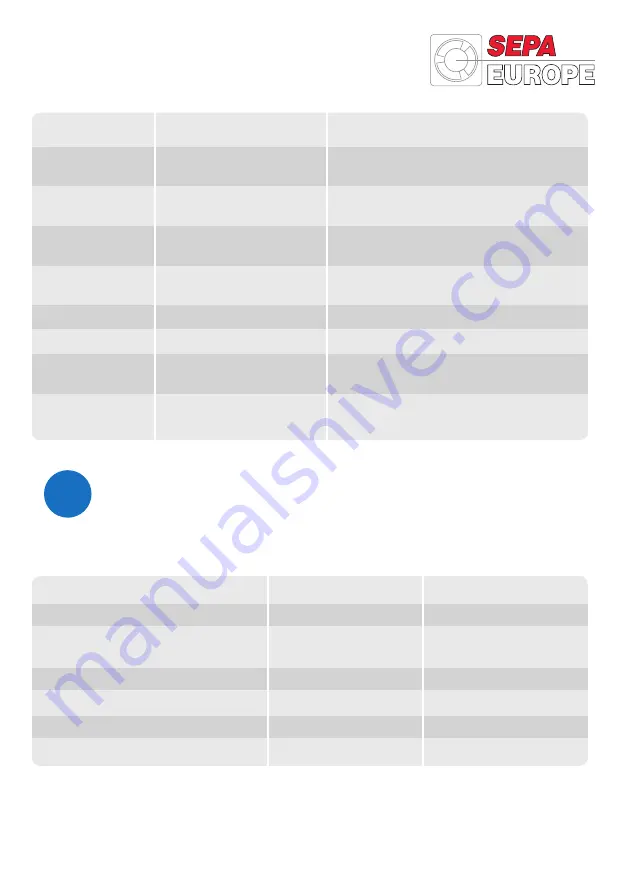

Fault/Error

Possible Cause

Possible Remedial Action

Motor does not

Mechanical blocking

Switch off, de-energize and eliminate

rotate

blocking

Defective mains voltage

Check mains voltage, re-connect

voltage supply

Defective connection

Rectify connection, see pin assignment

(Data Sheet)

Motor is too hot

Allow motor to cool down/identify

cause of fault

Electronics defect

Exchange product

Motor winding interrupted

Exchange product

Ambient temperature too

Reduce ambient temperature

high

if possible

Impeller runs

Unbalance of rotating

Clean product. If still running untrue

untrue

parts

after cleaning, exchange product

In the event of further faults, please contact

SEPA

EUROPE GmbH

.

Safety inspection

What requires inspecting?

How to check??

Frequency

Casing of protection against

Visual inspection

Min. ½ yearly

accidental contact

Product for damage

Visual inspection

Min. ½ yearly

Fixation of product

Visual inspection

Min. ½ yearly

Fixation of connection cables

Visual inspection

Min. ½ yearlys

Insulation of wires

Visual inspection

Min. ½ yearly

i