Diaphragm Relief Valve

Operating Instructions

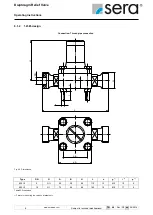

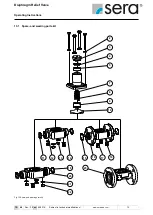

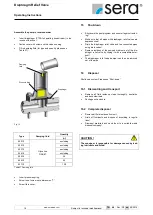

TA 48

Rev.

13 en

05/2016

Subject to technical modifications!

www.sera-web.com

17

17

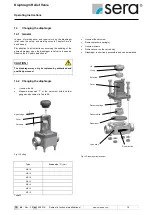

Clearance Certificate

NOTE!

Inspection / repair of machines and machine parts is only

carried out after the opposite clearance certificate was

filled in correctly and completely by authorized and quali-

fied personnel.

NOTE!

Acceptance will be refused if parts are returned to the

manufacturer without a proper clearance certificate

.

All industrial companies are obligated by the legal provisions

for occupational health, e.g. the workplaces ordinances, the

Ordinance on Hazardous Substances, the regulations for pre-

vention of accidents and the environmental protection regula-

tions such as the Waste Management Act and the German

Household Water Act to protect their employees or man and

the environment from detrimental effects when handling haz-

ardous substances.

Should special safety precautions be necessary despite careful

draining and cleaning of the product the necessary information

are to be provided.

Machines which are operated with radioactive media shall only

be

inspected

and/or

repaired

in

the

safety

area of the owner by a

sera

specialized fitter.

The clearance certificate is part of the inspection-/repair order.

sera

reserves the right to refuse acceptance of the order for

other reasons.

NOTE!

Please make a copy and leave the original with the operat-

ing instructions!

(can also be downloaded from: www.sera-web.com)