20

www.sera-web.com

OPERATION

NOTE

The sensitivity is set to 50% at the factory. This corresponds to a minimum conductivity of the dosing medium of approx.

45 µS/cm. The minimum conductivity at 100% sensitivity is 5 µS/cm.

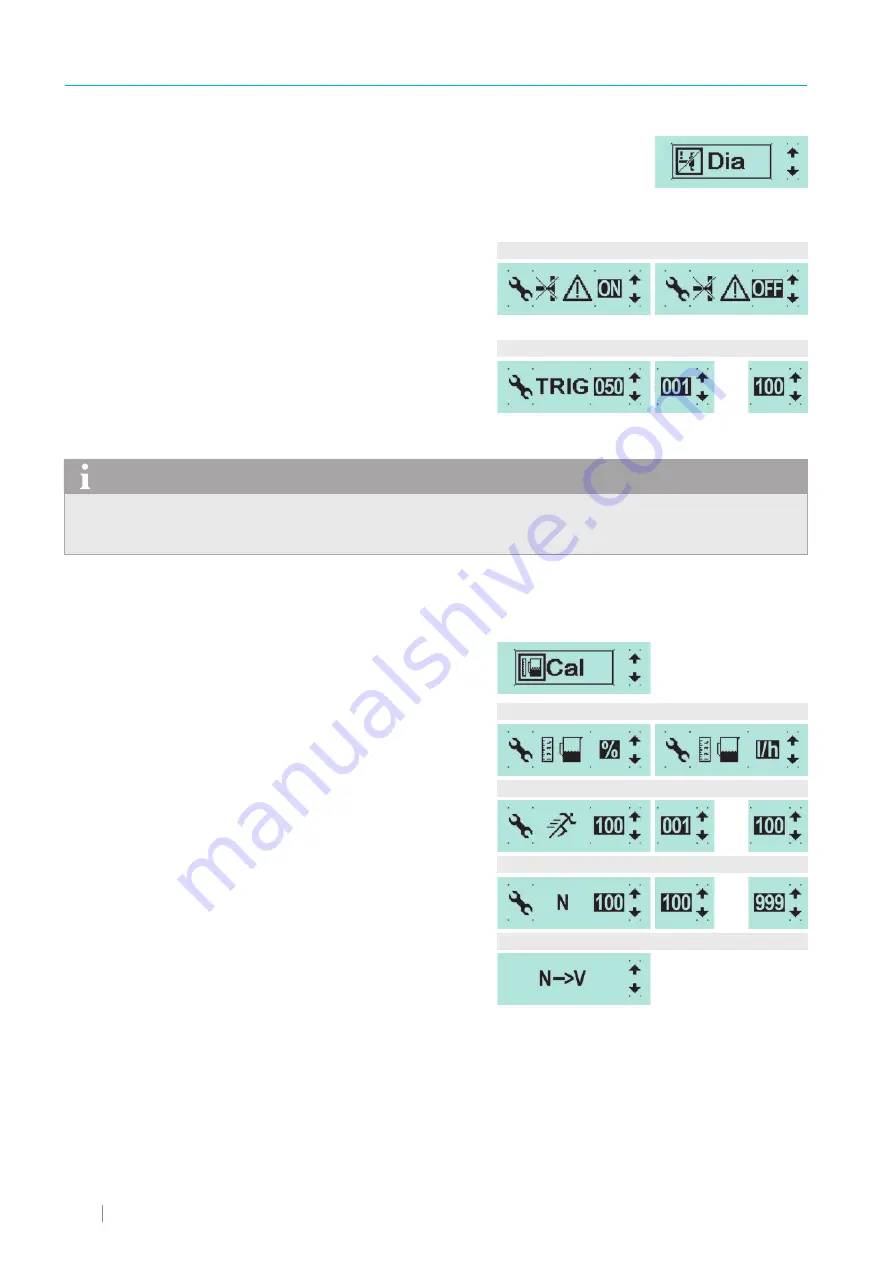

Diaphragm monitoring

Diaphragm monitoring is installed in every pump. It is used for monitoring

the delivery diaphragm.

The following items can be adjusted:

■

INPUT SIGNAL

Selection between switch-off (OFF) of the diaphragm monitoring and

a configuration as NO contact (for diaphragm pumps "e" and stepper

motor pumps or NC contact (for diaphragm pumps "ML" and "KM").

■

SENSITIVITY

Input of the sensitivity of the diaphragm rupture monitoring in percent.

For pumps with a diaphragm rupture electrode DRD, an adjustment

to the conductivity of the pumped medium is possible. In the case of

poorly conductive media, the sensitivity must be set to a high value

(e.g. 100% at approx. 4 µS/cm).

The sensitivity of ML and KM pumps must not be adjusted.

Input signal

Sensitivity

...

Calibration of the delivery rate display

The calibration is used to activate the flow rate indicator.

Calibration procedure

■

Lead the suction line into a calibration pot filled with the dosing medi-

um – the pressure line must be installed in final position, i.e. the pump

works under operating conditions.

■

When the suction pipe is empty, the dosing medium must be drawn in

(MANUAL operating mode, keep the pump running).

■

Note the fill level in the calibration pot (= base quantity).

■

Select the Calibration (Cal.) menu item under Settings.

■

First, enter the required number of strokes (

at least 200!

). The higher

the number of strokes, the more accurate is the calibration!

■

Enter frequency at which the pump should be operated later

(10...100%).

■

Select Start Calibration to start the calibration.

■

The dosing pump performs the specified number of strokes (wait for

process).

■

Determination of the delivered quantity (= difference between base

quantity and remaining quantity in the calibration pot).

■

Input of the determined delivered quantity (measured value).

Flow rate indicator

Stroke frequency

Number of strokes

Start calibration

...

...

Standard flow rate indicator

With the standard flow rate indicator, the entered target value is converted into the corresponding stroke frequency.

Internal calculation:

100% stroke frequency > calibrated: 10l/h

Setpoint: 8 l/h > 80% stroke frequency