2

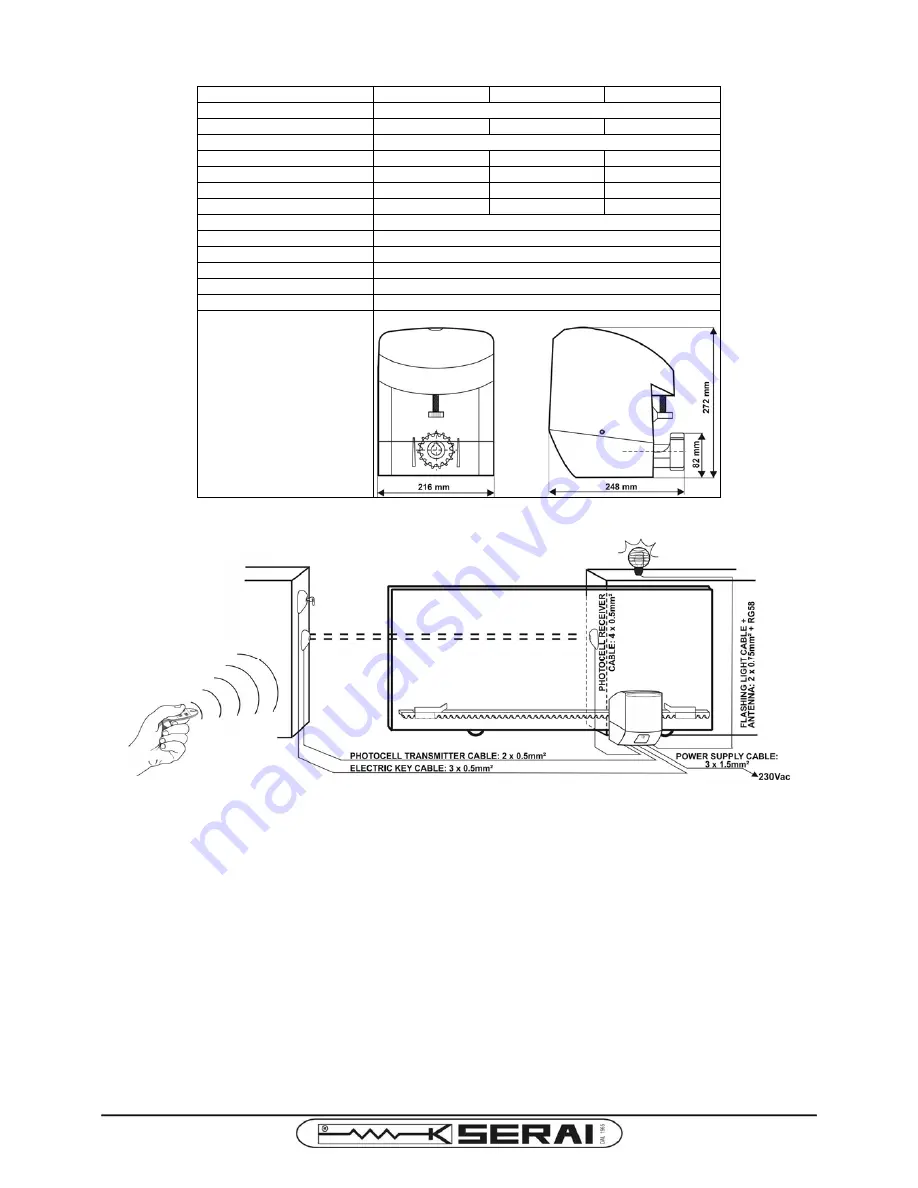

OPERATOR TECHNICAL DATA

MT/404

MT/604

MT/804

Operator characteristic

irreversible

Leaf max. weight

up to 400Kg

up to 600Kg

up to 800Kg

Operator supply voltage

230Vac ± 10% 50/60Hz

Capacitor 10µF

14µF

14µF

Max. absorbed current

2.1A

2.4A

2.8A

Absorbed power

245W

325W

335W

Starting thrust

350N

400N

490N

Operator strength regulated…

…through operator supply voltage adjustment

Normal leaf speed

9.7m/min@50Hz - 11.6m/min@60Hz

Operator thermal protection

150°C

Reduction ratio

1:28

Protection degree

IP44

Functioning temperature

-20 ÷ +60°C

Dimensions

216 x 272 x 248mm

ELECTRIC WIRING EXAMPLE

RECCOMENDATIONS FOR A SAFE WIRING IN EXTERNAL GENERAL TYPE ENVIRONMENTS

1. Verify the presence of an isolating switch upstream the installation, with an open contact clearance of 3mm or higher.

2. Before operating any wiring, switch OFF the isolating switch (the "0" symbol should be visible).

Verify that any source of

power is disconnected before wiring

. Particularly, the control unit should never be powered during the wiring phase, nor

when connecting devices or expansions to it.

3. Wire the components of the system using the following types of cables:

- devices powered @230Vac (control unit, operator, flashing light): use cables having section 1.5mm

2

/ 2.5mm

2

for length up

to 19m / 31m,

- devices SELV powered by the control unit (photocells, command buttons, electromechanical keys, etc.): use cables having

section 0.5mm

2

/ 0.75mm

2

for length up to 50m / 100m.

4.

Wire the earth connection in compliance with the standard prescriptions

.