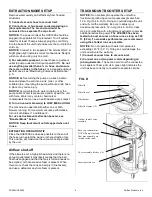

PARTS IDENTIFICATION

IMPORTANT! BEFORE FIRST USE:

The grab handle/vacuum hose guide (see Fig. A) is shipped inside the filter basket (Fig. D). Remove the hose

guide from the basket and install it as shown using the four screws provided. Do not overtighten the screws. The

unit is now ready to be set up as an extractor or booster. Two Velcro straps are also enclosed in the filter basket

(Fig. D). Use these straps to secure the extractor hose when not in use.

Vacuum inlet

(from

extraction tool).

Gravity drain hose

.

Keep capped and clipped

into place when not in

use.

Grab handle/vacuum

hose guide

. Direct hose

through guide before use

to avoid tipping. See

“Before First Use”

below for installation

instructions.

Filter basket cover

latches

. Remove cover

by lifting latches.

Cover assembly

latches

(×4)

FIG. A: FRONT

Also included:

25 ft.

section of 2 in. vacuum

hose.

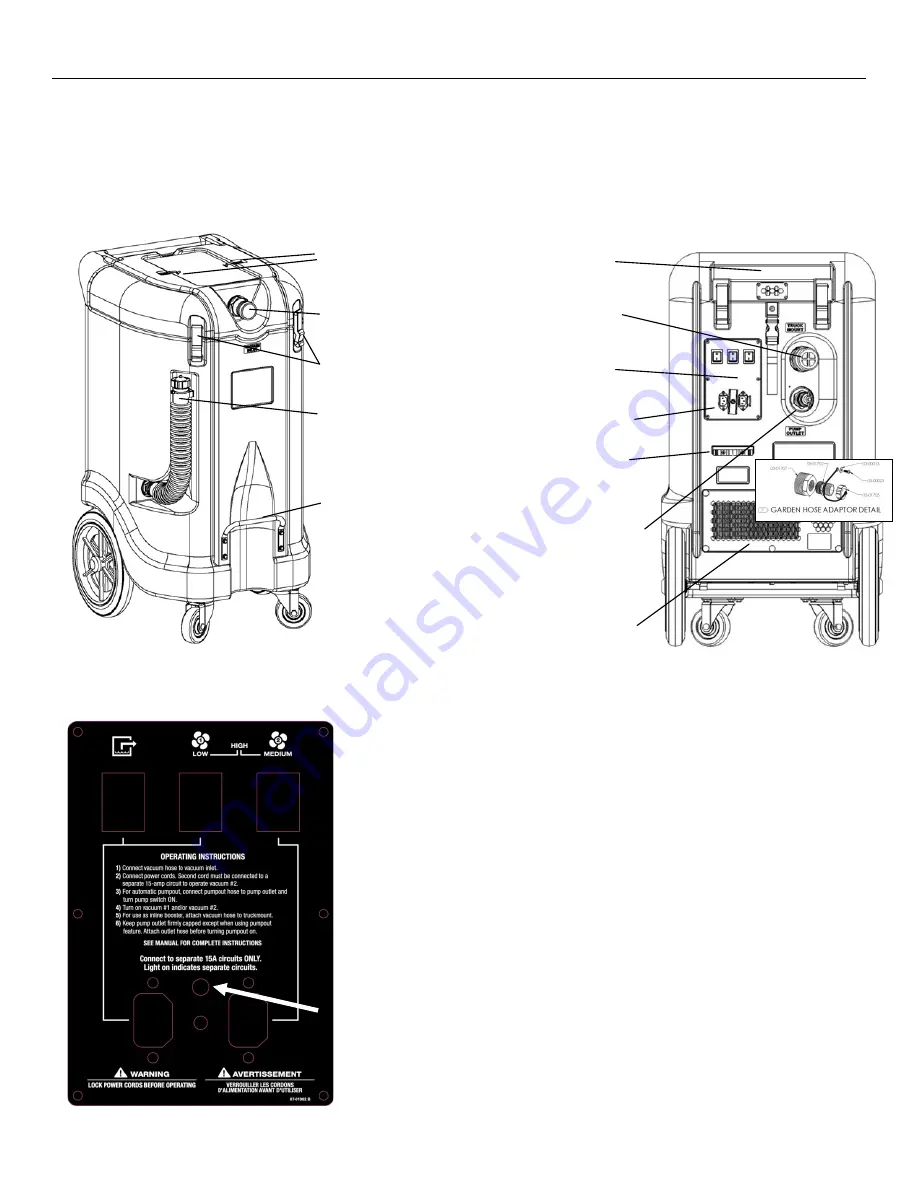

FIG. C: CONTROL PANEL DETAIL

P: Automatic pumpout switch.

Turn on to activate automatic pumpout

system.

NOTICE!

When automatic pumpout system is activated, sump

pump can turn on any time liquid is present in tank. Liquid may eject from

Pump Outlet with considerable force and cause injury. Always attach a drain

hose and place the end in a suitable drain before activating automatic

pumpout system.

A: Power cord socket.

Provides power to sump pump and blower 1.

B: Power cord socket:

Provides power to blower 2.

IMPORTANT! Secure power cords into sockets with lock.

1, 2: Vacuum blower switches.

LOW:

Blower 1 ON, Blower 2 OFF. Cord A required.

MEDIUM: Blower 1 OFF, Blower 2 ON. Cord B required.

HIGH:

Blower 1 ON, Blower 2 ON. Cords A and B required.

Independent circuit indicator light:

Glows bright green when the two cords

are properly connected to separate circuits. No light appears if a) the two cords

are connected to the same circuit or b) if only one cord is connected. When using

both power cords, do not operate the unit unless the green light is illuminated.

P

1

2

A

B

Power cord lock.

Secures

plugs in sockets.

Automatic

pumpout drain

outlet

. Pre-fitted with a 1½

in. outlet. To use a garden

hose, replace with the

supplied ¾ in. fitting (inset).

Keep capped when not in use.

Vacuum outlet.

Connect

to truckmount for use as

booster. Keep capped

when not in use.

Handle

Control panel

and

power cord sockets

.

Details in Fig. C.

Power cord retention

clips

. Secure cord(s) here

while using the unit.

HEPA exhaust filter grill

.

Thumbscrews allows easy

filter replacement.

FIG. B: REAR

SP004 HVE3000

3

Dri-Eaz Products, Inc.