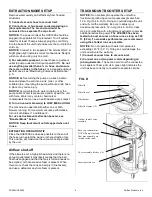

Using a

Philips screwdriver

, remove the pump intake

cover retention screw and the plate from the bottom of the

pump. Clean off any debris from intake area. Replace plate

when finished.

Wipe out tank with a clean rag.

Reassembly

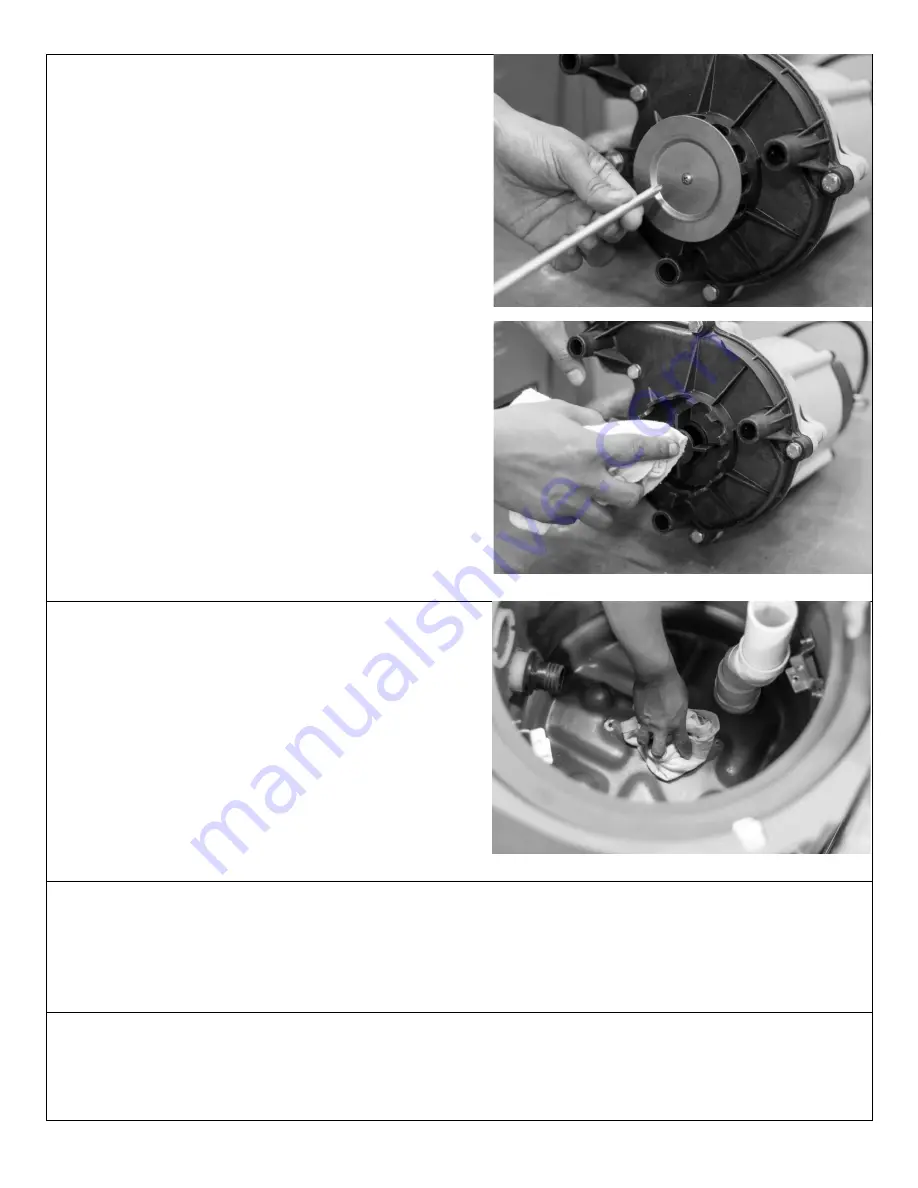

Lower pump back into bottom of tank and fold handle down. Ensure that the pump feet are fully seated.

Replace pump retention bracket. Push excess power cord back through cord grip and retighten cord grip. The cord should

be slack, but should not hang down and interfere with the operation of the float or the float arm assembly.

Reinstall the float ball assembly. Replace the cover assembly. The unit is now ready to use.

Replacing HEPA filter

See Fig. B. Replace when the filter is visibly dirty. To access the filter, remove the filter cover plate thumbscrews and lift

off the plate. Replacement filters are sold in packs of four. Ask for Dri-Eaz part no. F503 or Sapphire part no. 20-045.

SP004 HVE3000

9

Dri-Eaz Products, Inc.