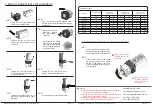

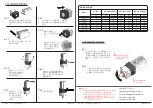

4. MOTOR CONNECTIVETY WITH GEARBOX

SESAME MOTOR CORP.

:

http://www.sesamemotor.com.tw/

E-mail: info@sesamemotor.com.tw

TEL: +886-4-2561-0011

FAX: +886-4-2562-7766

Check the motor and gearbox size.

Clean the mounting surface.

4.1

Take off the plug from the adapter plate.

Revolve the set collar until the bolt is aligned

with the hole.

4.2

Make sure the motor

shaft size. Choose

the right bushing if

necessary.

4.4

As installing on flatted

shaft, be sure to align the

collet gap over the flat and

the set collar bolt perpen-

dicular to the flat.

Tighten the mounting screws in

1~4 order with torque wrench to

5% specified torque.

4.5

Tighten the mounting screws in 1~4

order with torque wrench to speci-

fied torque.

4.7

Tighten the set collar bolt with

torque wrench to specified torque.

4.6

Power on the motor. Slowly drive the

motor and adjust its mounting status

until the gearbox is driven smoothly.

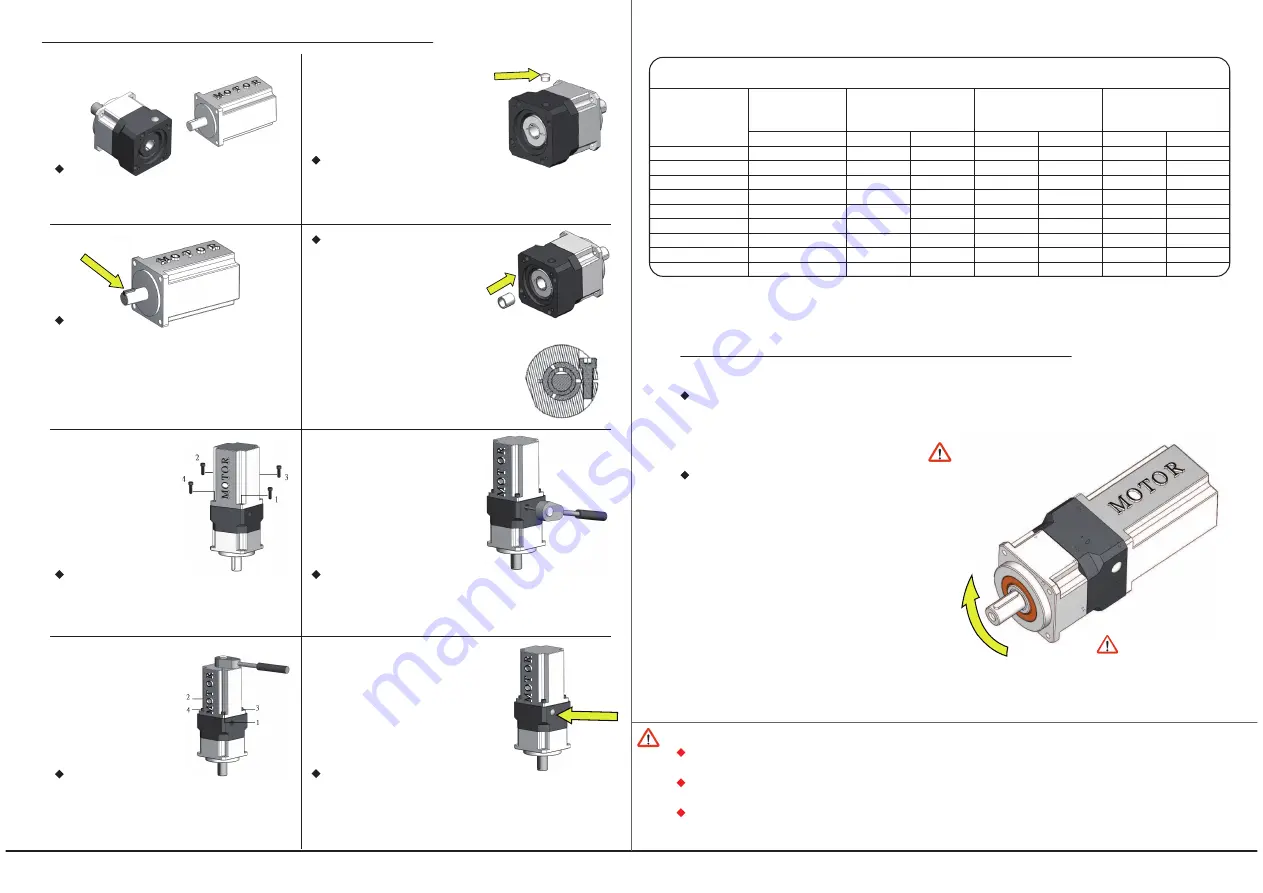

5.1

If the problem could not be solved

via the procedures above, please

DO NOT take apart of the motor,

contact SESAME for technical sup-

port right away.

5.2

Attention

Apply our product with other, please ensure it matchother’s

requirement, specification, or limitation.

Customer need to recheck our product is

suitable for their

current system or machinery usage.

If customer is neglecting for rechecking, then

Sesame is

not responsible for any cause

there might occur.

Put the plug back on the adapter plate.

4.8

Remove the key from the motor

shaft. Mounting the balance key if

necessary.

4.3

Ensure the plug was

installed before start

the motor.

。

Do not touch any

rotating component

when the gearbox

is running.

Page 3 / 4

Page 4 / 4

SESAME MOTOR CORP. / Planetary Gearbox Operation Manual V1.3

SESAME MOTOR CORP. / Planetary Gearbox Operation Manual V1.3

5.

TEST RUN & TROUBLE SHOOTING GUIDES

Bolt Size

Width Across Flats

Strength 8.8

Tightening Torque

Strength 10.9

Tightening Torque

Strength 12.9

Tightening Torque

Tightening Torque

In-lb

19

44

87

151

364

709

1232

1976

3038

N-m

2.1

4.9

9.8

17

41

80

139

223

343

In-lb

16

37

73

124

302

594

1028

1648

2534

N-m

1.8

4.1

8.2

14

34

67

116

186

286

In-lb

12

27

55

98

222

434

753

1214

1860

N-m

1.3

3

6.1

11

25

49

85

137

210

mm

2.5

3

4

5

6

8

10

12

14

M3*0.5P

M4*0.7P

M5*0.8P

M6*1P

M8*1.25P

M10*1.5P

M12*1.75P

M14*2P

M16*2P