5

MAINTENANCE: DEFLATING – CLEANING - FOLDING – STORAGE

1. Remove oars/paddles and other accessories.

2. To deflate, unscrew the valve insert and open the valve(s) cap.

3. Clean and check the item as well as all the accessories after each use. Rinse it thoroughly making sure to remove

any residues of salt if used in salt water. Use a mild soapy solution, do not use detergents or any type of silicone-

based products. Make sure that the product is completely dry before putting it away.

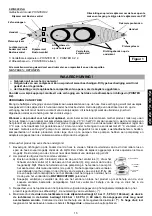

4. Fold the sides into the middle, then roll it up from the opposite end of the valves (so remaining air can escape from

the valves); start again if you feel there is still some air in the tubes.

5. When fully deflated, close the plug.

6. When storing your inflatable, keep it in a clean and dry place that is not affected from major variations in

temperature and other damaging factors. You may store it deflated and rolled up in a bag or assembled and lightly

inflated. Store it away from rodents.

CAUTION!

Water will enter between the outer hull and inside chambers, this is O.K; however, whenever you take this

item out of the water and deflate it, allow for it to air out and dry, neither the skin/hull or the inside chambers

will suffer from water damage, but stagnant water could cause mildew and foul odor.

HOW TO REPAIR SMALL PUNCTURES

You can repair small punctures with the included repair kit. Please note that in order for the repair to be successful, the

humidity level should be less than 60 %, temperature between 65°F/77°F or 18°C/25°C. Avoid carrying out repairs in

the rain or in direct sunlight.

To access the chambers, open the appropriate zip fastener. The zip fastener for the main chamber and the safety

chamber is located inside the kayak. The zip fastener for access to the floor chamber is located on the bottom at the

bow and the stern.

Check that the tube is fully deflated and lies flat.

1. Draw the shape of the patch exactly where it will be applied, cut a round patch at least 2” / 5 cm larger than the

cut/damaged area.

2. Clean the damaged area and the corresponding side of the patch with a grease remover of the alcohol type and

allow for it to dry for 5 minutes.

3. Apply 3 thin layers of glue on both the patch and the damaged area, allow for it to dry for 5 minutes between

layers until the glue feels tacky.

4. When the third layer of glue is dry, apply the patch without pressing and adjust the positioning if required, press

the air bubbles which may have formed under the patch by smoothing the patch with a round object such as a

spoon, do this procedure by starting in the center of the patch towards the outside, clean the excess glue with a

solvent.

Drying: 12 hours.

WARNING!

Perform all of your repairs in a well-ventilated area.

Avoid inhaling glue vapors or swallowing.

Avoid contact with the skin or the eyes.

Keep all repair materials (glue, solvents, etc.) away

from children’s reach.

Note:

The repairs on the weldings must not be glued.

In this case, chamber needs to be replaced.

E

N

G

L

I

S

H

Summary of Contents for POINTER K1

Page 76: ...76 1 C 4 mbar 0 06 PSI POINTER K2 1 2 K1 K2 300...

Page 77: ...77 1 2 3 4 5 6 60 18 C 25 C 1 5 cm 2 5 3 3 5 4 12...

Page 88: ...88 3 1 4 0 06 60 SEVYTEST 1 Sevytest 1 Sevytest 1 C 4 POINTERTM K2 1 2 K1 K2 2 A C K...

Page 89: ...89 300 1 2 3 4 5 6 60 18 C 25 C 1 5 2 5 3 3 5 4 12 A C K...

Page 90: ...90...

Page 93: ...93 N B 1 C 4 0 06 PSI POINTER K2 1 2 K1 K2 N B 300...

Page 94: ...94 1 2 3 4 5 6 60 18 C 25 C 1 5 2 5 3 3 5 4 12...

Page 95: ...95...

Page 96: ......