Gear Units for Trolley Drive Systems - Operating Instructions

11

6

Inspection and maintenance intervals

6

Inspection / Maintenance

6.1

Inspection and maintenance intervals

Table 2: Inspection and maintenance intervals

6.2

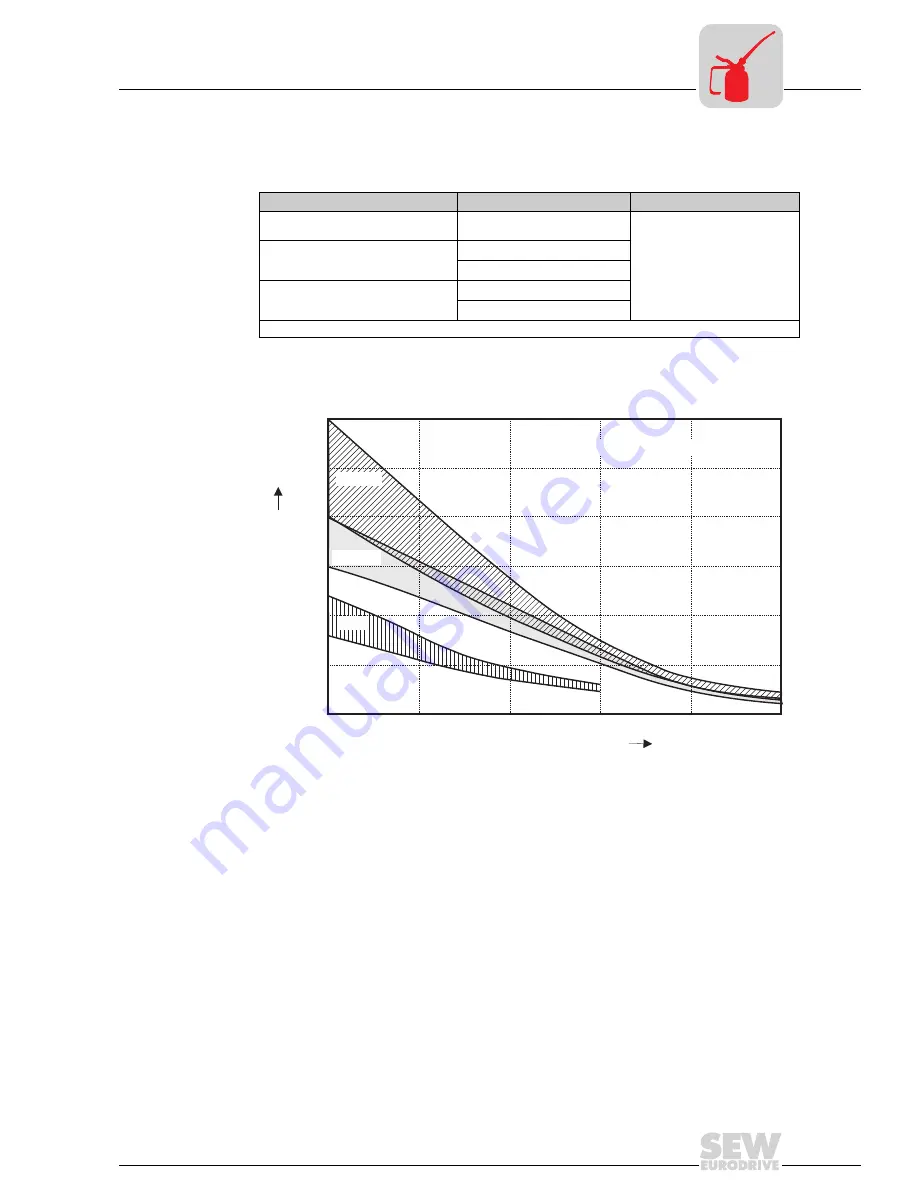

Lubricant change intervals

03357AEN

Figure 3: Change intervals for standard gear units under normal environmental conditions.

Change the oil more frequently when using special versions subject to more severe/

aggressive environmental conditions!

Interval

What to do?

→

Section

Every 3000 machine hours

At least every six months

Check the oil

see Section 6.3

Depending on operating conditions

(

→

Figure 3) at least every 3 years

Change mineral oil

Renew the anti-friction bearing

Depending on operating conditions

(

→

Figure 3) at least every 5 years

Change synthetic oil

Renew the anti-friction bearing

Spiroplan

®

gear units HW30 are lubricated for life and, therefore, are maintenance-free.

5000

10000

15000

20000

25000

30000

[h]

CLP PG

CLP HC

CLP

120

[°C]

110

100

90

80

70

0

Oper

at

ing hour

s

Oil bath steady-state temperature

Average value per type of lubricant at 70° C

Summary of Contents for HK40

Page 2: ...SEW EURODRIVE ...