6

12

Gear Units for Trolley Drive Systems - Operating Instructions

Inspection and maintenance

6.3

Inspection and maintenance

Do not mix synthetic lubricants with each other and do not mix synthetic and mineral

lubricants!

Oil is the standard lubricant.

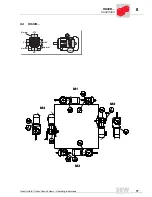

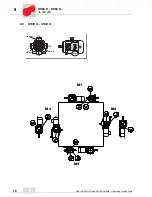

The location of the oil level plug, the oil drain plug and the breather plug for the different

mounting positions can be found in the corresponding figures (see section 8.1).

Checking

the oil level

1. Disconnect the drive and secure against unintentional switch-on!

Wait until the gear unit has cooled down – Danger of burns!

2. For modified mounting positions refer to Section 3.3!

3. For gear units with oil level plug:

Remove oil level plug, check oil level and adjust if necessary, replace oil level plug.

Checking the oil

1. Disconnect the drive and secure against unintentional switch-on!

Wait until the gear unit has cooled down – Danger of burns!

2. Remove some oil from the oil drain plug.

3. Check the oil consistency:

– viscosity

– if the oil is visibly strongly contaminated, it is recommended to change it sooner

than specified in the maintenance intervals in section 6.1

4. For gear units with oil level plug:

Remove oil level plug, check oil level and adjust if necessary, replace oil level plug.

Changing the oil

Change the oil only when the gear unit is at operating temperature.

1. Disconnect the drive and secure it against unintentional switch-on!

Wait until the gear unit has cooled down – Danger of burns!

Note: However, the gear unit must still be warm, otherwise the high viscosity of

excessively cold oil will make it harder to drain the oil correctly.

2. Place a container underneath the oil drain plug.

3. Remove the oil level screw, breather plug/breather valve and oil drain plug.

4. Drain all the oil.

5. Screw in the oil drain plug.

6. Fill new oil of the same type through the breather hole. In other cases please consult

the SEW service department.

– Fill to oil volume in accordance with the mounting positions (see Section 8.1) or

the details given on the name plate.

– Check at the oil level screw.

7. Screw the oil level plug back in.

8. Install breather plug/breather valve.

Summary of Contents for HK40

Page 2: ...SEW EURODRIVE ...