9

20

Gear Units for Trolley Drive Systems - Operating Instructions

Recommended lubricants for SEW drives

9.2

Recommended lubricants for SEW drives

01 805 492e

Gear

unit

type

0

°C

+50

+100

Lubricant

type

DIN (ISO)

ISO viscosity

resp.

NLGI class

-10

+40

CLP

(CC)

VG 220

Mobilgear

630

Shell Omala

220

Klüberoil

GEM 1-220

Aral Degol

BG 220

BP Energol

GR-XP 220

Tribol

1100/220

Meropa 220

Optigear

BM 220

Renolin

CLP 220

-25

+80

CLP

PG

VG 220

Mobil

Gl

yg

o

y

le 30

Shell Tivela

WB

Klübersynth

GH 6-220

Aral Degol

GS 220

BP Enersyn

SG-XP 220

Tribol

800/220

Synlube

CLP 220

Optiflex A

220

-40

+80

VG 220

Mobil

SHC 630

Shell Omala

220 HD

Klübersynth

GEM 4-220

Aral Degol

PAS 220

Tribol

1510/220

Pinnacle

EP 220

Optigear Syn-

thetic A 220

Renolin Unisyn

CLP 220

-40

+40

VG 150

Mobil

SHC 629

Klübersynth

GEM 4-150

-20

+25

VG 150

VG 100

Mobilgear

629

Shell Omala

100

Klüberoil

GEM 1-150

Aral Degol

BG 100

BP Energol

GR-XP 100

Tribol

1100/100

Meropa 150

Optigear

BM 100

Renolin

CLP 150

-30

+10

VG 68-46

VG 32

Mobil

D.T.E. 15M

Shell Tellus

T 32

Klüberoil

GEM 1-68

Aral Degol

BG 46

Tribol

1100/68

Anubia

EP 46

Optigear

32

Renolin

B 46 HVI

-40

+10

CLP

HC

VG 32

Mobil

SHC 624

Klübersynth

GEM 4-32

Cetus

PAO 46

-40

-20

HLP

(HM)

VG 22

VG 15

Mobil

D.T.E. 11M

Shell Tellus

T 15

ISOFLEX

MT 30 ROT

BP Energol

HLP-HM 10

Aircraft

H

y

dr. Oil 15

0

+40

Oil

CLP

(CC)

VG 680

Mobilgear

636

Shell Omala

680

Klüberoil

GEM 1-680

Aral Degol

BG 680

BP Energol

GR-XP 680

Tribol

1100/680

Meropa 680

Optigear

BM 680

Renolin

CLP 680

-20

+60

CLP

PG

VG 680 1)

Mobil Glygoyle

HE 680

Klübersynth

GH 6-680

BP Enersyn

SG-XP 680

Tribol

800/680

Synlube

CLP 680

-30

+80

CLP

PG

VG 460

Mobil

SHC 634

Shell Omala

460 HD

Klübersynth

GEM 4-460

-40

+10

CLP

PG

VG 150

Mobil

SHC 629

Klübersynth

GEM 4-150

-20

+10

CLP

(CC)

VG 150

VG 100

Mobil

D.T.E. 18M

Shell Omala

100

Klüberoil

GEM 1-150

Aral Degol

BG 100

BP Energol

GR-XP 100

Tribol

1100/100

Meropa 100

Optigear

BM 100

Renolin

CLP 150

-25

+20

CLP

PG

VG 220 1)

Mobil

Gl

yg

o

y

le 30

Klübersynth

GH 6-220

Tribol

800/220

Synlube

CLP 220

Optiflex A

220

-40

0

CLP

HC

VG 32

Mobil

SHC 624

Klübersynth

GEM 4-32

Cetus

PAO 46

-20

+40

SEW

PG

VG 460 3)

Klüber SEW

HT-460-5

-40

+10

API

GL5

SAE 75W90

(~VG 100

)

Mobilube SHC

75 W90-LS

-30

+40

Food

ind. oil

HCE

VG 460

Shell Cassida

Fluid GL 460

Klüberöl

4UH1-460

Aral Eural

Gear 460

Optileb

GT 460

-20

+40

Bio oil

E

VG 460

Klüberbio

CA2-460

Optisynt

BS 460

-25

+60

00 2)

Glygoyle

Grease 00

Shell Tivela

Compound A

Klübersynth

GE 46-1200

Multifak

6833 EP 00

-15

+40

000 - 0 2)

Mobilux

EP 004

Shell Alvania

GL 00

Aralub

MFL 00

BP Energrease

LS-EP 00

Multifak

EP 000

Longtime

PD 00

Renolit

SF 7- 041

= lubricants supplied at the assembly plants SEW USOCOME (F)

1) Helical-worm gear units with PG oil. Consult SEW-Eurodrive

C

LP PG = polyglycol

CLP = mineral oil

= lubricants supplied at the assembly plants SEW EURODRIVE (BRD)

2) Consult SEW-Eurodrive for other gear units

CLP HC = synt

h.

hydrocarbon

HLP = hydraulic oil

= synthetic lubricants

3) Special lubricant for Spiroplan gear units only

E = diester oil (water contamination class WGK 1)

= mineral lubricants

Please note: critical startup behaviour at low temperatures.

HCE = synth. hydroc diester oil (USDA - H1 approval)

KBTS/Ga/Vi

Standard

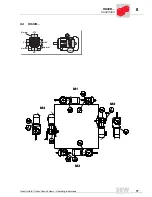

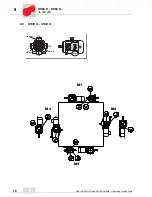

Helical gear units, helical-bevel

gear units, parallel gear units

Helical-worm gear units

Ambient temperature range

CLP (CC)

Lubrication table for SEW drives

*

*

*

*

*

*

*

*

R, K, F, S

gear units

*

DIN

51181

Grease

R 32

R 302

*

W gear

units

Standard

Standard

Standard

CLP HC

CLP HC

Summary of Contents for HK40

Page 2: ...SEW EURODRIVE ...