8

Inspection and maintenance

Inspection and maintenance intervals

Operating Instructions – MOVIGEAR

®

classic

69

8

Inspection and maintenance

8.1

Inspection and maintenance intervals

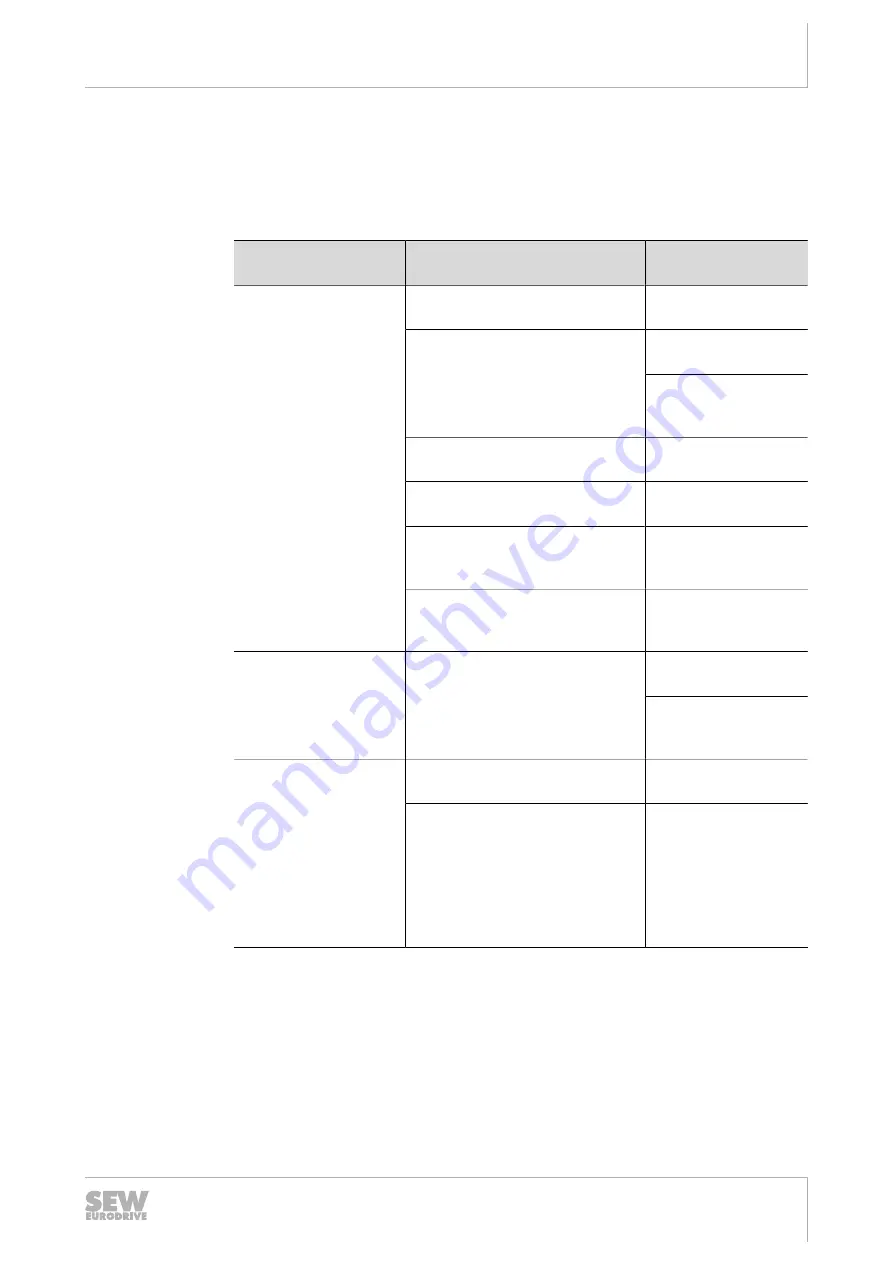

The following table shows the inspection and replacement intervals for the drive units:

Time interval

What to do?

Who is permitted to

perform the work?

Every 3000 operating

hours, at least every 6

months

Check running noise for possible

bearing damage

Qualified personnel at

customer site

In the event of a bearing damage:

Have the bearing replaced by

SEW‑EURODRIVE Service or

qualified personnel trained by

SEW‑EURODRIVE.

SEW‑EURODRIVE

Service

Qualified personnel

trained by

SEW‑EURODRIVE

Visual inspection of the seals for

leakage

Qualified personnel at

customer site

In the event of a leakage at the

output oil seal: Change the oil seal

Qualified personnel at

customer site

In the event of any other leakage:

Contact SEW‑EURODRIVE

Service.

SEW‑EURODRIVE

Service

For gear units with a torque arm:

Check rubber buffers and replace

them if necessary

Qualified personnel at

customer site

Recommendation:

Every 20 000 operating

hours

1)

Have the motor inspected by

SEW‑EURODRIVE Service or

qualified personnel trained by

SEW‑EURODRIVE.

SEW‑EURODRIVE

Service

Qualified personnel

trained by

SEW‑EURODRIVE

The drive units are

equipped with long-term

lubrication. Depending

on the operating condi-

tions and the oil temper-

ature, the oil must be

changed at least every

5 years (see chapter

"Lubricant change inter-

vals").

Change synthetic oil

Qualified personnel at

customer site

Replace oil seal on output end (do

not install it in the same track)

Qualified personnel at

customer site

25805134/EN – 07/2018

Summary of Contents for MGFAT1-DSM-C/PE

Page 2: ...SEW EURODRIVE Driving the world...

Page 123: ......