4

Mechanical installation

Required tools and resources

Operating Instructions – MOVIGEAR

®

classic

21

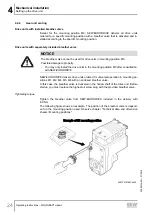

4.2

Required tools and resources

•

Set of wrenches, set of screwdrivers, set of socket wrenches

•

Torque wrench

•

Mounting device

•

Compensation elements (shims and spacing rings), if necessary

•

Fasteners for output elements

•

Lubricant (e.g. NOCO

®

fluid)

•

Standard parts are not included in the delivery

4.2.1

Installation tolerances for shaft ends

Diameter tolerance in accordance with DIN 748:

•

ISO H7 for hollow shafts

4.2.2

Tolerances for torque ratings

The specified torques must be adhered to with a tolerance of +/- 10%.

4.3

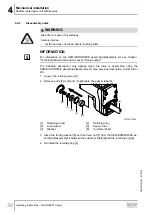

Installation requirements

Check that the following conditions have been met:

•

The information on the drive unit's nameplate must match the voltage supply sys-

tem.

•

The drive is undamaged (no damage caused by transportation or storage).

•

Ambient temperature according to the operating instructions, nameplate and lub-

ricant table in chapter "Technical data / Lubricants".

•

The drive must not be assembled in the following ambient conditions:

– Potentially explosive atmosphere

– Oils

– Acids

– Gases

– Vapors

– Radiation

•

For special designs: The drive is designed in accordance with the actual ambient

conditions.

•

Clean the output shafts and flange surfaces thoroughly to ensure they are free of

anti-corrosion agents, contamination or similar. Use a commercially available

solvent. Do not expose the sealing lips of the oil seals to the solvent – damage to

the material.

•

When the drive is installed in abrasive ambient conditions, protect the output end

oil seals against wear.

25805134/EN – 07/2018

Summary of Contents for MGFAT1-DSM-C/PE

Page 2: ...SEW EURODRIVE Driving the world...

Page 123: ......