4

Mechanical installation

Setting up the drive unit

Operating Instructions – MOVIGEAR

®

classic

22

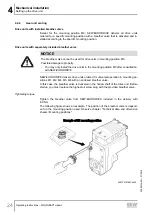

4.4

Setting up the drive unit

4.4.1

Notes

•

Only mount the drive units to the plant structure together with a torque arm. Install-

ation without a torque arm is not permitted.

•

Clean the shaft ends thoroughly to ensure they are free of anti-corrosion agents

(use a commercially available solvent). Do not expose the bearings and sealing

rings to the solvent – damage to the material.

•

Carefully align the drive unit and the driven machine to avoid placing any unac-

ceptable strain on the shaft ends.

•

Do not butt or hammer the shaft end.

•

Ensure that cooling air supply is unobstructed and that air discharged by other

units does not influence cooling.

•

Use suitable cable glands for the supply leads (use reducing adapters if neces-

sary).

•

Seal the cable entry well.

•

Clean the sealing faces of the cover well before reassembling the unit.

•

Restore the corrosion protection if necessary.

•

Check the validity of the degree of protection using the information in the operating

instructions and the data on the nameplate.

Changing the mounting position

Observe the following information when you operate the drive unit in a mounting posi-

tion other than the one indicated in the order:

•

Adjust the position of the breather valve.

•

If present, adjust the position of the pressure compensation fitting.

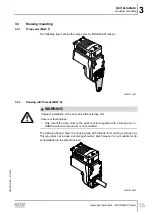

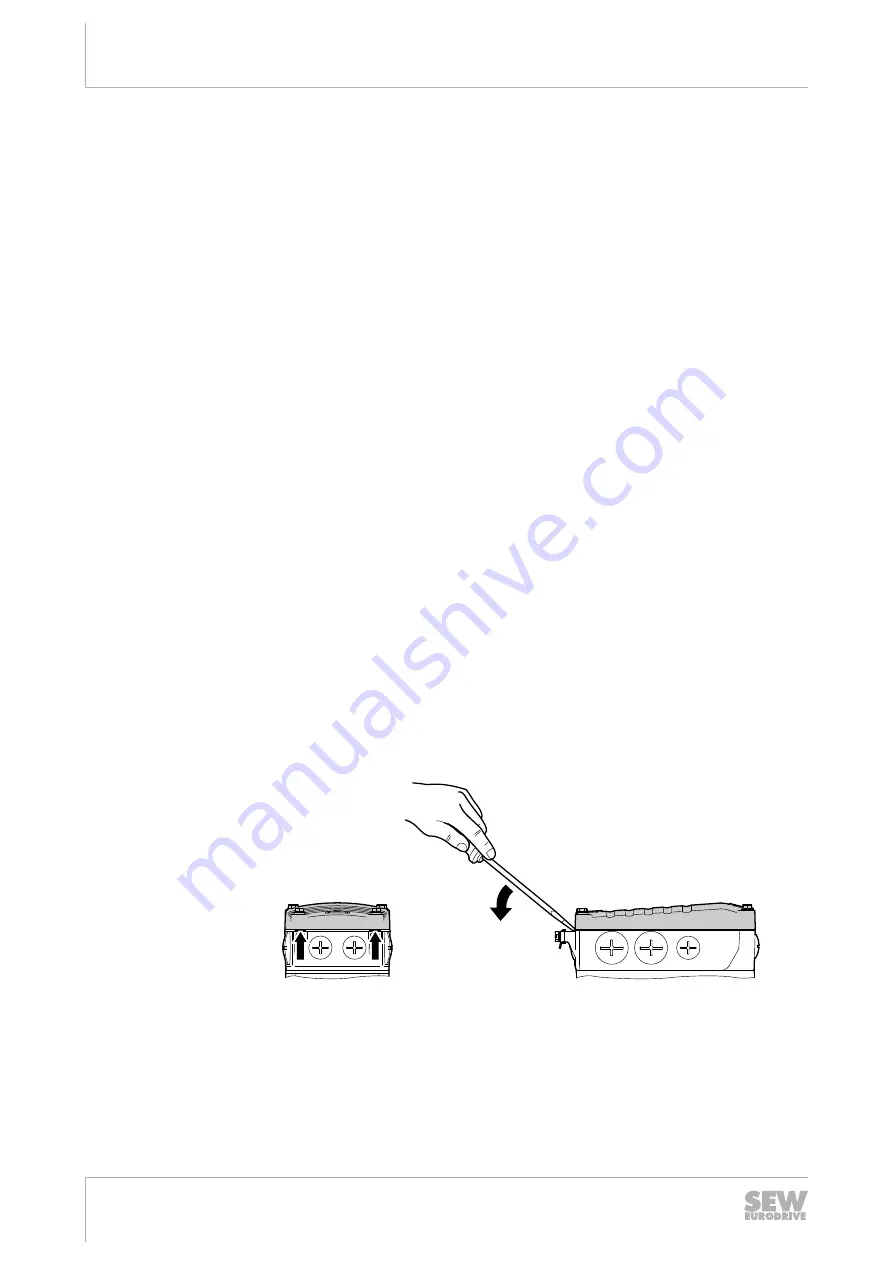

4.4.2

Removing the cover

The following figure shows how you can lever off the cover in the intended places:

21512521483

25805134/EN – 07/2018

Summary of Contents for MGFAT1-DSM-C/PE

Page 2: ...SEW EURODRIVE Driving the world...

Page 123: ......