7

Electrical installation

Safe digital inputs (F-DI.)

Manual – MOVISAFE

®

CS..A Safety Card (Version 2)

53

7.5.3

Signal monitoring

The signal monitoring detects when the input signal is in an undefined state (unstable

state) for too long. The maximum duration for which an unstable state is permitted is

calculated from the set filter time multiplied by the parameter value of the parameter

Signal monitoring

(Index 8704, Subindex 8). The function can also be deactivated with

the value "0" via the

Signal monitoring

parameter. The safety card responds with an

input error if the signal monitoring is active and the maximum duration has been ex-

ceeded.

7.5.4

Pulsed voltage supply and crossfault monitoring

For information about parameter setting and operating principles, refer to chapter

"Startup".

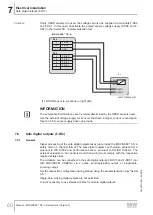

If crossfault monitoring is used for a safe digital input F-DI, the following assignment

between the sensor supply F-SS and the safe digital input F-DI must be adhered to:

•

F-DI00, F-DI02 via the respective sensor to F-SS0.

•

F-DI01, F-DI03 via the respective sensor to F-SS1.

Crossfault monitoring can be selected separately for each input.

If crossfault monitoring is not active (e.g. for sensors with OSSD output), the sensors

can be supplied either from F-SS0 / F-SS1 or from a24 V supply that has the

same ground reference.

WARNING

Danger due to incorrect setting of the parameter

F-DI. Connection type

when con-

necting dual-channel sensors. There is no redundancy or discrepancy check with

the "Single-channel" setting.

Severe or fatal injuries.

•

When connecting dual-channel sensors, the parameter

F-DI. connection type

must be set to "Dual-channel (non-equivalent/equivalent)".

Only the connection variants shown below are permitted for safe applications! Also

note the assignment of the connection variants of the safe digital inputs to the cat-

egory structures pursuant to EN ISO 13849-1.

28482271/EN – 03/2019