PERFORMANCE CHECKLIST

If stitch is not formed:

x

Needle is not fully inserted into the needle clamp body.

x

Needle is inserted into the wrong side.

x

Needle is defective.

x

Bobbin thread (bottom) is not threaded correctly into the bobbin case hole.

If machine skips stitches:

x

Needle is not straight and sharp.

x

Needle is inserted on wrong side.

x

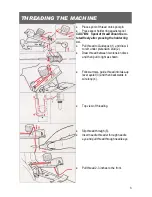

Machine is not properly threaded.

x

Fabric is not firmly held down.

If needle thread (top) breaks:

x

Machine is not properly threaded.

x

Needle thread (top) tension is too tight.

x

Thread is not freely unwinding from spool.

x

Needle is inserted on wrong side.

If bobbin thread (bottom) breaks:

x

Bobbin thread (bottom) is too tight.

x

Thread is entangled in bobbin case.

x

Bobbin thread (bottom) is threaded incorrectly into bobbin case.

If fabric does not feed:

x

Presser foot is not lowered.

If needle breaks:

x

Needle is defective.

x

Needle is not inserted fully into needle clamp body.

x

Fabric is pulled excessively while sewing.

x

Needle thread (top) is caught somewhere.

x

Needle thread (top) tension is too tight.

If needle does not move:

x

Battery power is weak.

x

Batteries are not inserted correctly.

x

Foot switch plug is not inserted fully.

15

Summary of Contents for SuperLockstitch SP-403

Page 20: ...Notes 19...

Page 21: ...Notes 20...