Manual – MOVI-PLC® advanced DHE41B/DHF41B/DHR41B Controller

31

4

Installing the MOVI-PLC® advanced DHF41B controller

Mounting/Installation Instructions

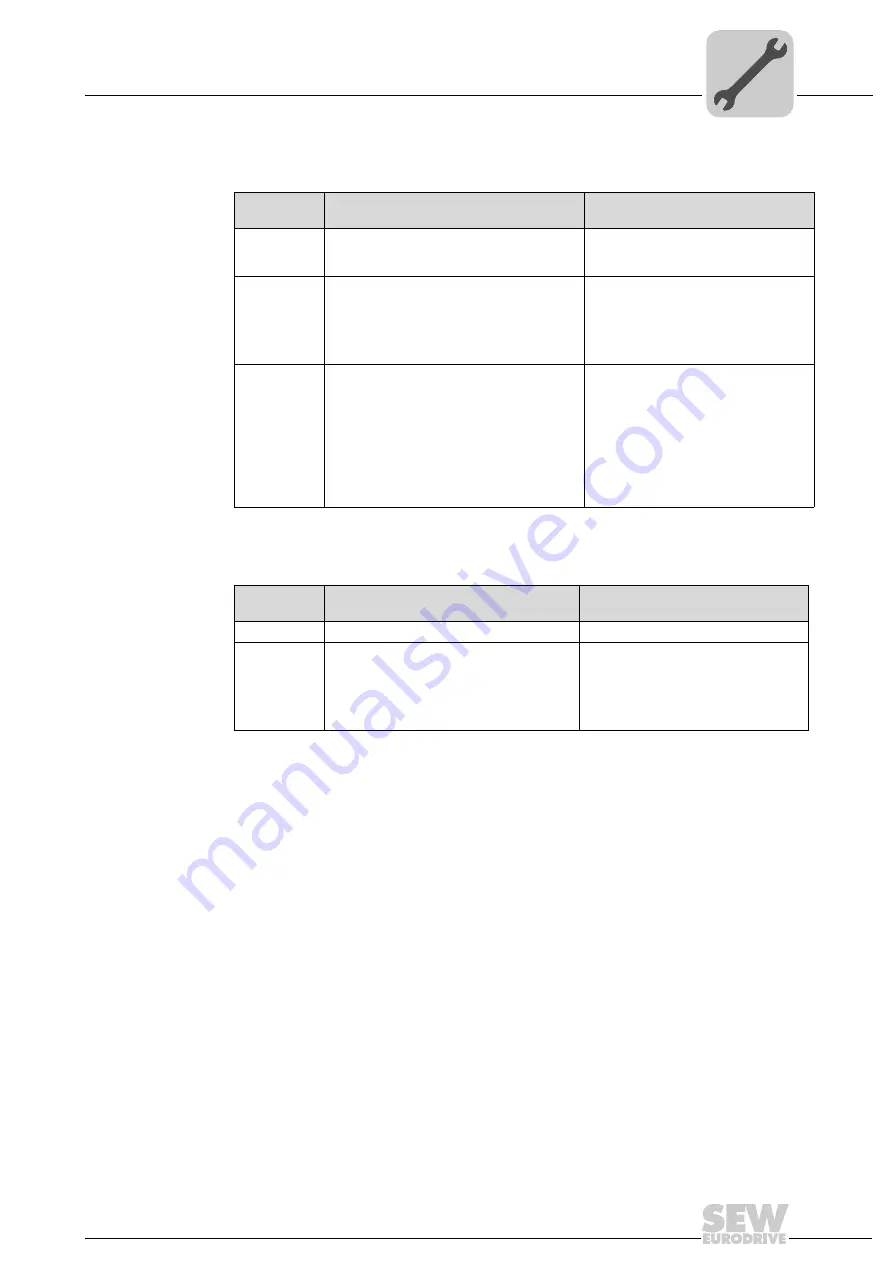

LED L17

(Fault Profibus)

The LED

L17 (Fault

Profibus) indicates that communication via the PROFIBUS inter-

face is working properly.

LED L18

(Run Profibus)

LED

L18 (Run Profibus)

indicates the proper functioning of the PROFIBUS electronics

(hardware).

Status of the

LED L17

Diagnostics

Troubleshooting

Off

•

The MOVI-PLC

®

advanced

DHF41B con-

troller exchanges data with the PROFI-

BUS-DP master (data exchange status).

-

Red

•

Connection to the DP master has failed.

•

The MOVI-PLC

®

advanced

DHF41B con-

troller does not recognize the PROFIBUS

baud rate.

•

Bus interruption has occurred.

•

PROFIBUS-DP master not in operation.

•

Check the PROFIBUS connection on

the unit.

•

Check project planning of the

PROFIBUS DP master.

•

Check all the cables in the PROFI-

BUS network.

Flashing red

(1 Hz)

•

The MOVI-PLC

®

advanced

DHF41B con-

troller recognizes the baud rate, but the DP

master does not communicate with

MOVI-PLC

®

advanced

DHF41B.

•

The MOVI-PLC

®

advanced

DHF41B con-

troller was either not configured in the DP

master or it was configured incorrectly.

•

Check and correct the PROFIBUS

station address set in the

MOVI-PLC

®

advanced

DHF41B con-

troller and in the configuration soft-

ware of the DP master.

•

Check and correct the configuration

of the DP master.

•

Use the GSD file

SEW_6007.GSD

with the designation

MOVI-PLC

for

configuration.

Status of the

LED L18

Diagnostics

Troubleshooting

Green

•

PROFIBUS hardware OK.

-

Flashing

green

(1 Hz)

•

The PROFIBUS station address set on

the DIP switches is more than 125. If the

PROFIBUS station address is set to a

value higher than 125, MOVI-PLC

®

advanced

DHF41B will use PROFIBUS

station address 4.

1. Check and correct the PROFIBUS

station address on the DIP switches.

2. Switch on all drive inverters again.

The modified PROFIBUS address

will only take effect after a restart.