Operating Instructions – Electronic Motor DRC.-..-DAC

201

12

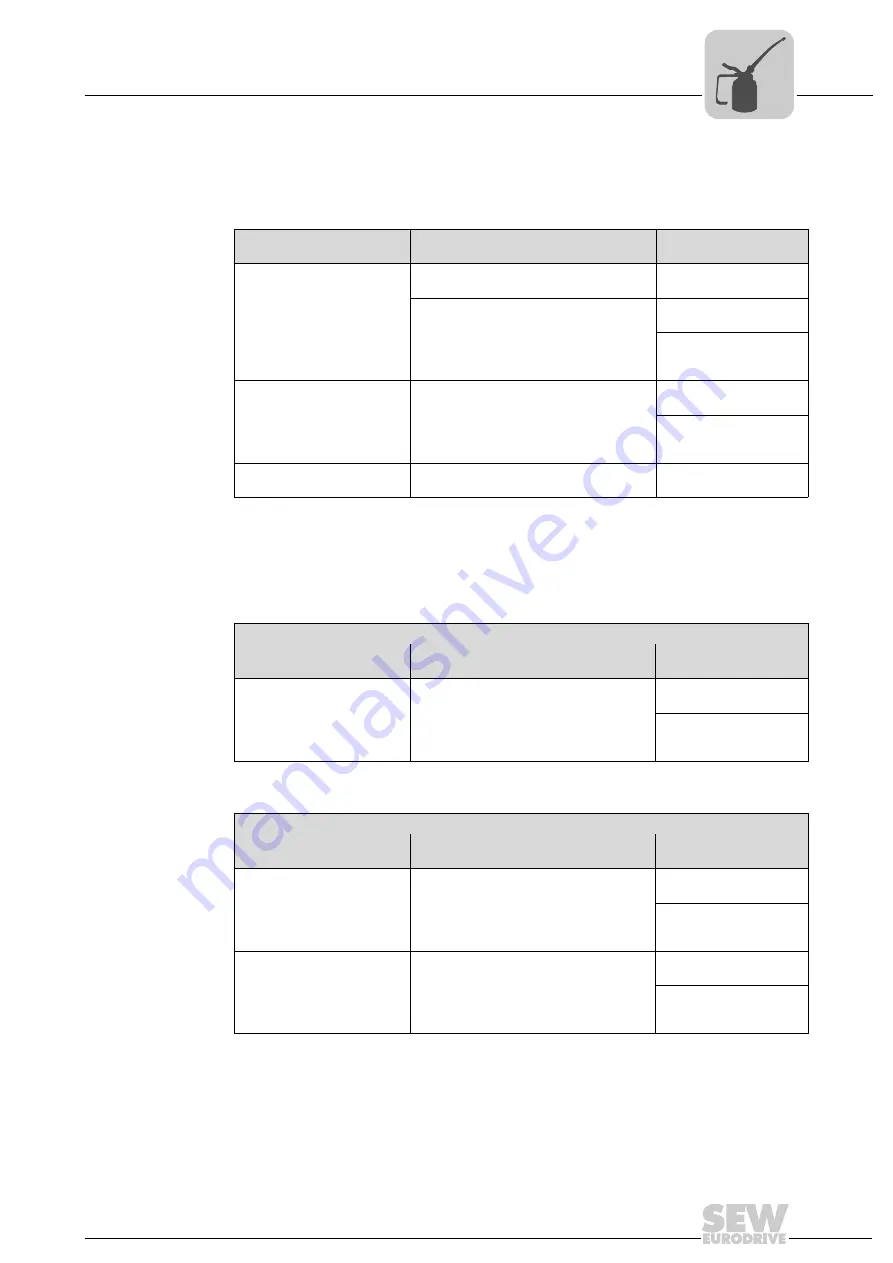

Inspection and maintenance intervals

Inspection and Maintenance

12.2 Inspection and maintenance intervals

12.2.1 Motor

The following table shows the inspection intervals for DRC motors:

12.2.2 Brake

The following table shows the inspection intervals for DRC brakes:

Time interval

What to do?

Who is permitted to

perform the work?

Every 3,000 hours of opera-

tion, at least every 6 months

Check running noise for possible bearing

damage

Qualified personnel at

customer site

In the event of a bearing damage: Have the

bearing replaced by SEW-EURODRIVE

Service or qualified personnel trained by

SEW-EURODRIVE.

SEW-EURODRIVE

Service

Qualified personnel

trained by SEW-

EURODRIVE

Recommendation:

Every 10,000 hours of

operation

1)

1) Wear times are influenced by many factors. The system manufacturer must calculate the required

inspection/maintenance intervals individually in accordance with the project planning documents.

Have the motor inspected by SEW-

EURODRIVE Service or qualified person-

nel trained by SEW-EURODRIVE.

SEW-EURODRIVE

Service

Qualified personnel

trained by SEW-

EURODRIVE

Varying (depending on

external factors)

Touch up or renew the surface

protection/anticorrosion coating.

Qualified personnel at

customer site

If used as a holding brake:

Time interval

What to do?

Who is permitted to

perform the work?

Every 2 years

1)

1) Wear times are influenced by many factors. The system manufacturer must calculate the required

inspection/maintenance intervals individually in accordance with the project planning documents.

Have the brake inspected by SEW-

EURODRIVE Service or qualified

personnel trained by SEW-EURODRIVE.

SEW-EURODRIVE

Service

Qualified personnel

trained by SEW-

EURODRIVE

If used as a holding brake with braking work done in case of emergency braking operations

Time interval

What to do?

Who is permitted to

perform the work?

Every 3,000 hours of opera-

tion, every 2 years at the

latest

1)

1) The system manufacturer must calculate the required inspection/maintenance intervals individually in

accordance with the project planning documents.

Have the brake inspected by SEW-

EURODRIVE Service or qualified person-

nel trained by SEW-EURODRIVE.

SEW-EURODRIVE

Service

Qualified personnel

trained by SEW-

EURODRIVE

After this much braking work

has been done:

•

BY1C (DRC1): 40 MJ

•

BY2C (DRC2): 65 MJ

Have wear parts replaced by SEW-

EURODRIVE Service or qualified personnel

trained by SEW-EURODRIVE.

SEW-EURODRIVE

Service

Qualified personnel

trained by SEW-

EURODRIVE