Operating Instructions – Electronic Motor DRC.-..-DAC

223

13

Surface protection

Technical Data and Dimension Sheets

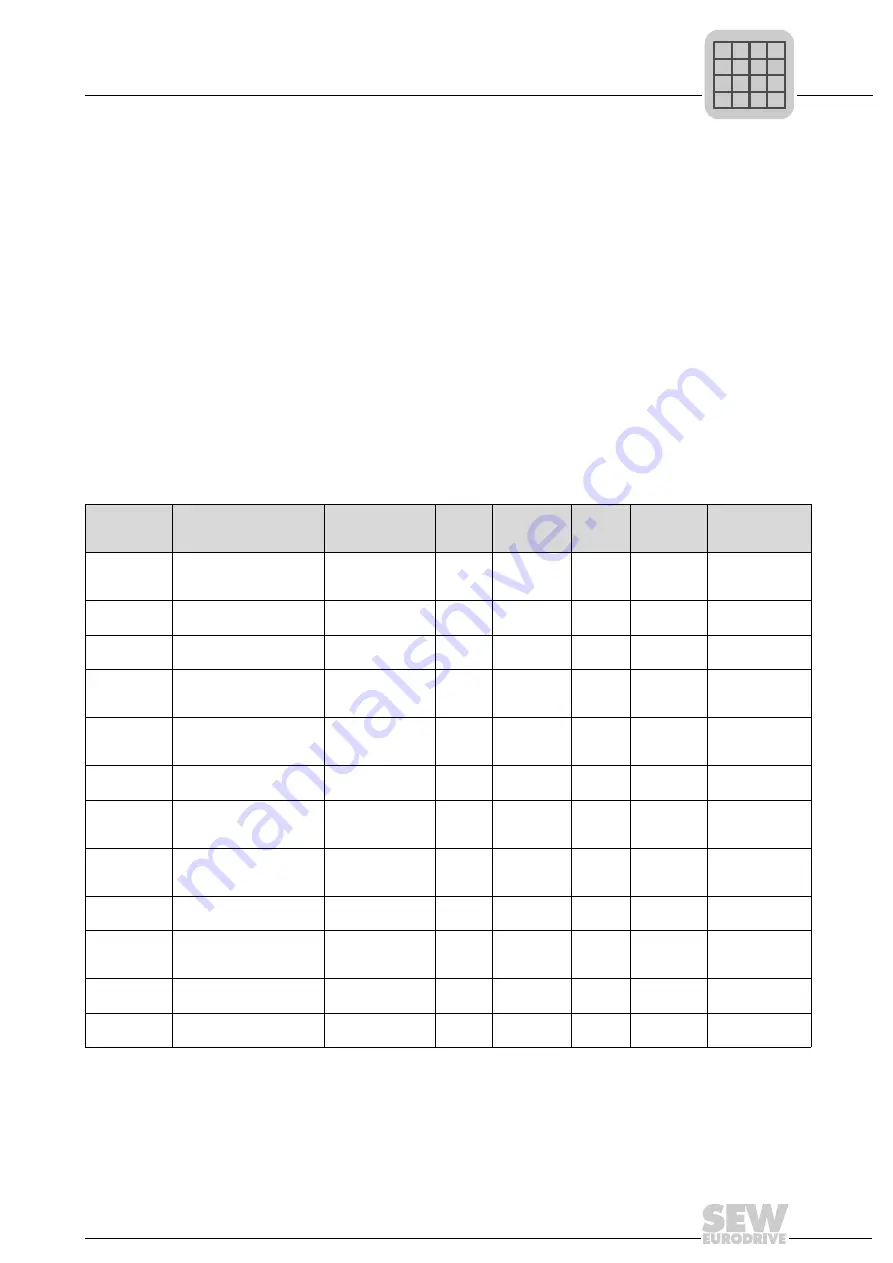

13.5.3 Resistance of OS4 surface treatment to cleaning agents

SEW-EURODRIVE has had the resistance of the base coat and top coat of the OS4

surface coating independently tested and certified for cleaning agents and disinfectants

from leading manufacturers.

Providing these recommended cleaning agents and disinfectants are used and that the

specified cleaning intervals, temperatures and cleaning schedules are complied with,

the best possible results can be achieved with ASEPTIC gearmotors in terms of service

life and performance.

The following prerequisites were applied to the testing cycle:

• The testing cycle (1500 cycles) simulated daily cleaning according to product-

specific instructions for a time period of five years.

• Evaluation took place approximately 7 days after regeneration.

• Evaluation of visual changes (color, degree of lustre) and changes in protective

properties according to DIN EN ISO 4628-1.

• OS4 coating system on steel or aluminum base.

• Cleaning agents supplied by Henkel-ECOLAB

®

Cleaning

agents

Product specification

Major

ingredients

Con-

centra-

tion

Load cycle

Test

temper-

ature

Decorative

changes

1)

Changes in

protective

properties

P3-topax 19

Alkaline foam cleaning

agent

Alkalis, surfac-

tants, complexing

agents

3%

20 min

60 °C

1

0

P3-topax 56

Acid foam cleansing agent

Acids, surfac-

tants, inhibitors

3%

20 min

60 °C

4

0

P3-topax 58

Acid foam cleaning agent

based on organic acids

Surfactants,

organic acids

5%

20 min

60 °C

0

0

P3-topax 66

Alkaline foam cleansing

agent and disinfectant

based on active chlorine

Alkalis, active

chlorine, surfac-

tants

5%

20 min

60 °C

2

0

P3-topax 68

Alkaline foam cleansing

agent with active chlorine

(suitable for aluminum)

Alkalis, active

chlorine, surfac-

tants

5%

20 min

60 °C

1

0

P3- topax 99

Alkaline foam disinfectant

Basis: Salts,

organic acids

2%

20 min

60 °C

3

0

P3-topactive

200

Alkaline cleansing agent

for operational cleansing

as TFC application

Alkalis, surfac-

tants, complexing

agents

4%

20 min

60 °C

1

0

P3-topactive

500

Acid cleansing agent for

operational cleansing as

TFC application

Inorganic acids,

surfactants

3%

20 min

60 °C

4

0

P3-oxonia

Disinfectant for closed

systems

Basis: Hydrogen

peroxide

1%

30 min

60 °C

1

0

P3-oxonia

active

Disinfectant for closed

systems

Basis: Hydrogen

peroxide, pera-

cetic acid

3%

10 min

20 °C

0

0

P3-topactive

DES

Foam and TFC-capable

disinfectant

Basis: Peracetic

acid, surfactants

3%

30 min

20 °C

0

0

P3-oxysan

ZS

Disinfectant for closed

systems

Basis: Peroxide

compounds

1%

30 min

20 °C

0

0

1) Assessment: 0 = No change, to 5 = Very severe changes

P

i

f

kVA

Hz

n