Operating Instructions – Electronic Motor DRC.-..-DAC

81

6

Startup with binary slave GLK30A in "Expert mode"

Startup

10.Check whether these parameters depend on mechanical controls and disable them,

if required, by adjusting the bit-coded selection box of parameter

index 10096.30

.

11.Change the selected parameters.

12.Check the functions of the DRC drive unit.

Optimize the parameters, if required.

13.Disconnect the PC from the DRC inverter.

14.Make sure the screw plug of the diagnostic interface has a seal and screw it in.

NOTICE

Loss of the ensured degree of protection if the screw plug of the diagnostic

interface is not installed or not installed correctly.

Damage to the DRC electronics cover.

• Make sure the screw plug of the diagnostic interface has a seal and screw it in.

15.Switch on the following voltages.

• AS-Interface voltage

• Line voltage

16.Set the required AS-Interface address.

• With a hand-held programming device

• With an AS-Interface master (see description of master)

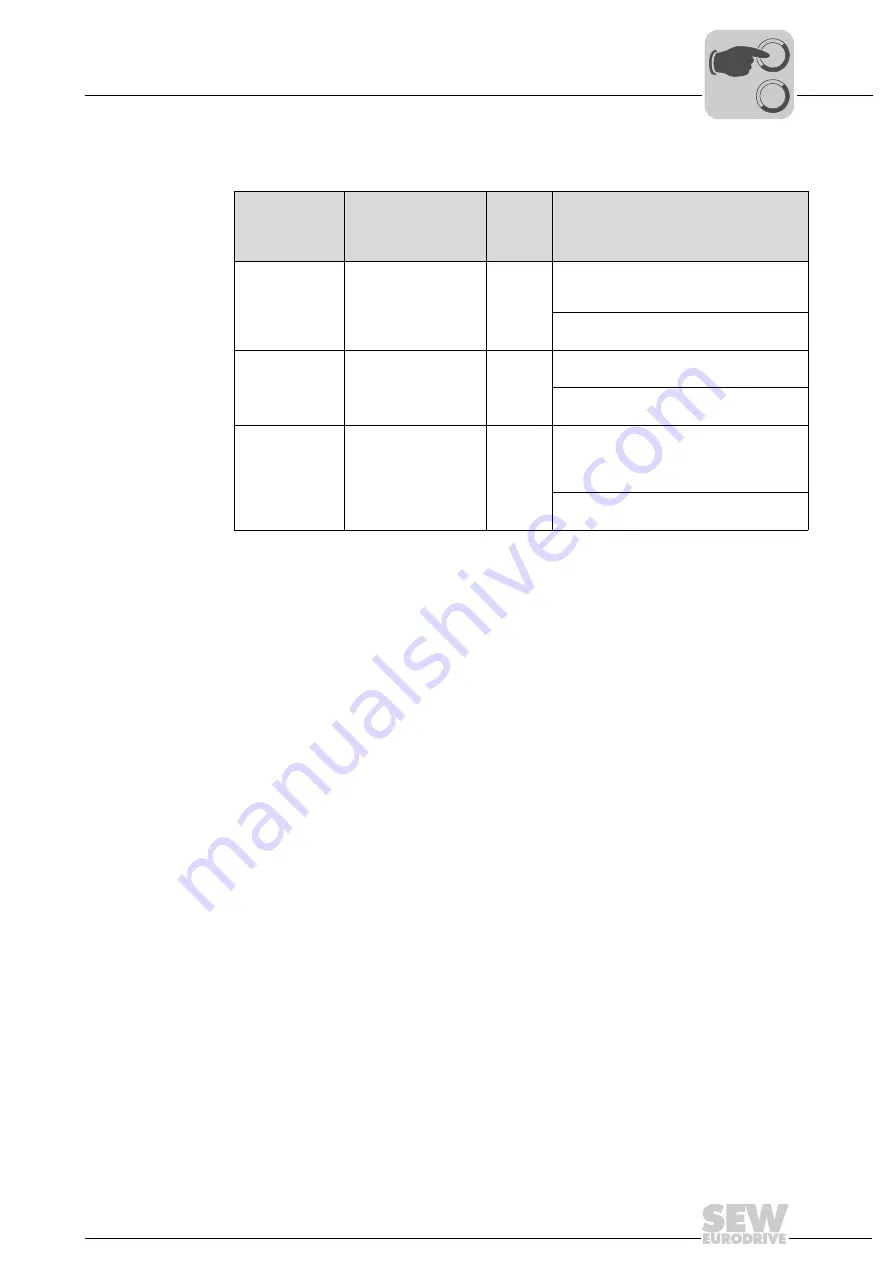

Mechanical

control element

Affected

parameter index

(command pcb)

Bit

of

index

10096.30

Effect of parameter index 10096.30

(deactivation of mechanical

control elements)

Setpoint

potentiometer f1

10096.35 setpoint n_f1

13

Bit not set:

Setpoint f1 is set with setpoint potentiometer

f1

Bit set:

Setpoint f1 is set using parameters

Switch f2

10096.36 setpoint n_f2

14

Bit not set:

Setpoint f2 is set with switch f2

Bit set:

Setpoint f2 is set using parameters

Switch t1

8807.0 Ramp t11 up

8808.0 Ramp t11 down

15

Bit not set:

The ramps are set with switch t1

(acceleration ramp time = deceleration ramp

time)

Bit set:

The ramps are set using parameters

00

I