72

Operating Instructions – MOVIDRIVE® MDR60A/61B

6

Explanation of the parameters

MDR61B1600/2500 – Parameters

P294 Integral time

current controller

Setting range: 0.00 – 7.50 – 10000.00 ms

Recommendation: Do not change the factory setting.

It might be necessary to adjust the current controller to poor supply system conditions

with high impedance. To do so, increase the integral time.

P295 Mains off tol-

erance time

Setting range: 0.000 – 5.000 ms

The supply and regenerative unit monitors the supply system and the DC link. In case

of faulty supply systems and brief power failures, you can set a delay time in the "Mains

off tolerance" parameter before the supply system monitor trips. A prerequisite for this

is that the DC link voltage does not fall below 435 V. If the voltage falls below this value,

the monitor trips without delay.

P296 U

z

reduced

Setting range: Yes/No

If you connect SEW units in sizes 0 to 6 to the supply and regenerative unit with line volt-

ages

≥

440 V, you have to set parameter U

z

reduced to "Yes". This avoids an excessive

voltage load of the connected consumers. This function generates additional inductive

reactive power.

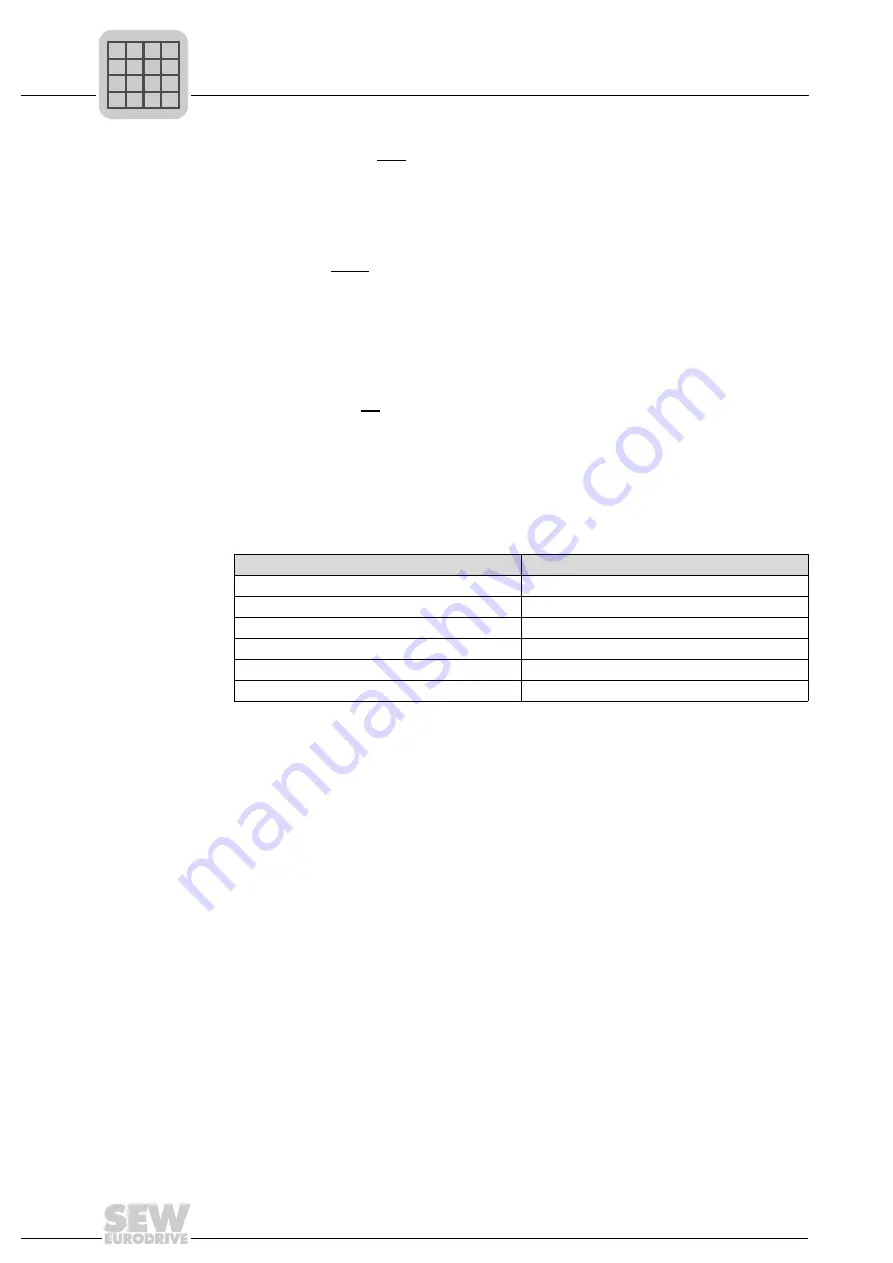

Automatic assignment:

P297 Regener-

ated energy

…kWh

Total of the active electrical energy that the regenerative power supply unit has fed back

into the supply system; storage cycle every 1 min.

P298 Effective

power display

…kW

Amount of power that is currently consumed or regenerated by the line inverter. Signed.

P299 Line voltage

…V

RMS value of line voltage

6.2.5

P4xx Reference signals

The following reference values are used for recording and reporting certain operating

states. All signals of parameter group P4xx can be read via binary outputs (

).

Important:

The signals are only valid if the inverter has signaled "ready" after switch-on

and there is no error display.

Line voltage

Controlled DC link voltage

AC 380 V

DC 644 V

AC 400 V

DC 670 V

AC 440 V

DC 700 V

AC 460 V

DC 700 V

AC 480 V

DC 700 V

AC 500 V

DC 710 V

P

i

f

kVA

Hz

n