3

Safety concept

Drive safety functions

Manual – MOVISAFE

®

CS..A Safety Card

23

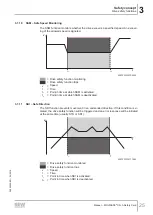

3.7.6

SOS – Safe Operating Stop

The SOS function prevents the motor from deviating from the stop position by more

than a specified value. The drive inverter delivers the power to keep the motor in posi-

tion. If the specified value is exceeded, the drive safety function will be triggered and

an error response will be initiated at the same time.

t

1

t

2

t

V

9007201225700491

= Drive safety function monitoring

= Drive safety function trips

v

= Speed

t

= Time

t

1

= Point in time when SOS is triggered.

t

2

= Point in time when SOS is deactivated.

3.7.7

SLA – Safely Limited Acceleration

The SLA function prevents a movement from exceeding a specified acceleration

value. If the permitted acceleration limit is exceeded, the drive safety function will be

triggered and an error response will be initiated at the same time.

t

1

t

2

t

V

9007201225705355

= Drive safety function monitoring

= Drive safety function trips

v

= Speed

t

= Time

t

1

= Point in time when SLA is activated.

t

2

= Point in time when SLA is deactivated.

24842532/EN – 04/2018