Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

81

7

Process data description

SEW Unit Profile

SLIP

Set to

SLIP

means the MOVIDRIVE

®

inverter interprets the trans-

mitted process output data word as slip compensation value.

Specifying the slip compensation via fieldbus automatically dis-

ables parameters

P324 Slip compensation 1

and

P334 Slip com-

pensation 2

.

Specifying the slip compensation via process data channel is only

technically meaningful in the

VFC N-CONTROL

operating mode

because the torque can be influenced directly by changing the slip

compensation.

The value range of this slip compensation value is identical with

the value range of parameter

P324 Slip compensation 1

and cor-

responds to a speed range of 0 - 500 rpm.

If the slip specified using process data is outside this value range,

the maximum will take effect when the minimum and maximum

values are exceeded.

1 digit = 0.2 / min

RAMP

Set to

RAMP

, the MOVIDRIVE

®

inverter considers the transmit-

ted setpoint value to be an acceleration or deceleration ramp. The

specified value corresponds to a time in ms and refers to a speed

change of 3000 rpm.

The rapid stop and emergency stop function is not affected by this

process ramp. When transmitting the process ramp via the field-

bus system, ramps t11, t12, t21 and t22 become ineffective.

1 digit = 1 ms

CONTROL WORD

1 / CONTROL

WORD 2

The assignment of process output data with control word 1 or 2

allows for activating nearly all the drive functions via fieldbus sys-

tem. For a description of control words 1 and 2, please refer to the

chapter "Control word definition".

SPEED [%]

Set to

SPEED [%]

means the MOVIDRIVE

®

inverter interprets the

setpoint transmitted in this process data word as speed setpoint in

percent.

The relative speed setpoint always refers to the currently applica-

ble maximum speed limit, which means either P302/312 or MAX.

SPEED or PO speed limit.

4000

hex

= 100 % n

max

IPOS PO-DATA

The setting

IPOS PO-DATA

has the effect that the drive inverter

does not use this process output data word for processing set-

points. The inverter system ignores the content of the process

output data word programmed to

IPOS-PO-DATA

and is available

for sole processing in the IPOS

plus®

control program.

Within IPOS

plus®

, you can use the command

GetSys PO-Data

to

directly access the process output data of the communciation

interfaces. For more detailed information, refer to the IPOS

plus®

positioning and sequence control system manual.

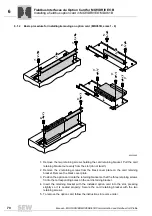

Three words

with individually

coded 16 bits

each can be

exchanged

between the

higher-level

controller and

IPOS

plus®

.

Assignment

Meaning

Scaling

Summary of Contents for MOVIDRIVE MDX60B

Page 2: ...SEW EURODRIVE Driving the world...

Page 142: ......

Page 143: ...SEW EURODRIVE Driving the world...